| Issue |

Sci. Tech. Energ. Transition

Volume 80, 2025

|

|

|---|---|---|

| Article Number | 47 | |

| Number of page(s) | 14 | |

| DOI | https://doi.org/10.2516/stet/2025027 | |

| Published online | 29 July 2025 | |

Regular Article

Development and performance analysis of a biogas reactor using livestock manure

1

University of Jeddah, College of Science, Department of Physics, Al-Faisaliyah, Jeddah 23445, Kingdom of Saudi Arabia

2

Faculty of Medicine, King Abdulaziz University, Prince Majid St, Jeddah 21589, Kingdom of Saudi Arabia

* Corresponding author: bushra5272@hotmail.com

Received:

19

October

2024

Accepted:

30

June

2025

Anaerobic biotechnology is a viable solution for recovering biomethane from organic waste, thereby mitigating GreenHouse Gas (GHG) emissions. This study investigated the development and performance of an anaerobic underground Fixed-Dome Reactor (GFDR) designed to optimise methane production from livestock manure, offering a sustainable approach to waste management and renewable energy generation. The reactor was evaluated using manure from horses, cows, camels, and sheep, and key operational parameters (total solids, volatile solids, total nitrogen, and pH) were monitored throughout the process. The biogas produced by the GFDR contained 56.40% methane and 34.80% carbon dioxide, demonstrating its efficiency in methane recovery. Additionally, the nutrient-rich digestate was assessed for its potential use as a biofertiliser, contributing to sustainable agricultural practices. This study provides a detailed characterisation of the feedstock and reactor performance, highlighting the ability of the system to reduce GHG emissions and promote sustainable waste-to-energy technologies. A preliminary economic feasibility analysis estimates that constructing a 22 m3 GFDR would be financially viable. This study underscores the cost-effectiveness of biomass energy recovery, although further advancements in sensor technologies and biogas production processes are necessary to enhance efficiency and reduce costs.

Key words: Biomethane / Fixed-dome / Digestate / Volatile fatty acids

© The Author(s), published by EDP Sciences, 2025

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

1 Introduction

Energy is an essential resource. As traditional energy sources are limited and potentially depleted, there is an urgent need to explore alternative and environmentally friendly energy sources [1]. In recent years, the world has turned to energy alternatives and has sought solutions to provide energy through the management of unwanted resources and materials. Biogas is an alternative energy source [2]. Biogas energy is both economical and widely available, and it can be easily converted into electricity and heat [3]. Currently, biogas can be processed to produce biomethane, which can be implemented into natural gas systems as an alternative to natural gas, utilised as vehicle fuel, and substituted for natural gas in industrial, residential, and commercial applications. Carbon dioxide (CO2) can be separated from biogas and utilised as an initial component to produce chemical fuels and as feedstock for greenhouses [4].

Biogas is characterised by its ability to generate energy from organic materials found in solid waste, such as industrial and agricultural waste, sewage sludge [5], animal manure from dairy farms [6], and food scraps from homes and restaurants [7]. The use of waste to produce biogas creates a healthier environment by treating the waste sustainably and ensuring environmental safety [8]. CO2 emitted from biomass into the atmosphere contributes to the global GreenHouse Gas (GHG) effect and exacerbates global warming caused by GHG emissions from burning fossil fuels [8–10]. Therefore, many countries have established biogas plants to mitigate these effects [11].

Biomass can produce biogas through anaerobic biodigestion and contains carbohydrate polymers (such as cellulose and hemicellulose), fats (lipids), lignin, and proteins [12]. It can be converted to biogas in two ways; the first method is uncontrolled Anaerobic bioDigestion (AD), which occurs in wetlands and landfills. The second is controlled AD, which is used in sewage and organic material treatment plants [13]. Methane (CH4) and CO2 constitute the largest part of biogas composition, with CH4 concentration ranging from 55% to 70% and CO2 from 30% to 45%; it includes a small amount of additional compounds like Hydrogen Sulfide (H2S), Ammonia (NH3), and Other Trace Compounds [14, 15].

The use of biomass for energy production dates back to the 19th century [16], with India constructing its first biogas plant at the beginning of the 20th century [17]. Recently, bioenergy generation has become increasingly popular [18]. Biogas is commonly used to produce transport fuel, heat, and electricity [19]. It offers several additional applications. Biogas rich in CH4 can be used as feedstock to produce materials and chemicals [20]. The amount of CH4 in the biogas determines its calorific value, which varies depending on its composition [21]. The energy content of CH4 has been well-documented in various scientific and engineering studies. The commonly cited value is approximately 36 MJ/m3. This value represents the heat of combustion of CH4, which is the energy released when CH4 is completely burned [22].

The AD process produces biogas by digesting organic matter inside a digester in the absence of oxygen. This process involves four functional groups: hydrolysis, acidogenesis, acetogenesis, and methanogenesis [23]. Carbohydrate and amino acid fermenters, Volatile Fatty Acid (VFA) oxidisers, and methanogens represent operationally complex microbial groups that play a role in the multistep microbiological processes of AD [24, 25]. In the first stage, complex organic compounds are broken down into smaller components, such as fatty acids, amino acids, and simple sugars. The intermediates produced during hydrolysis are transformed into acetic acid, hydrogen (H2), and CO2 by acid-forming bacteria during acidogenesis and acetogenesis. The last step in CH4 formation is methanogenesis [13]. Some AD processes can be classified into two stages. The first stage incorporates the first and second phases (Hydrolysis and Acidogenesis). This process creates VFAs and hydrogen, whereas the second stage incorporates the third and fourth phases (Acetogenesis and Methanogenesis) to yield CH4 [26]. Biogas generation ceases when hydrolysis and acetogenesis are inhibited. The optimisation of methanogenesis is challenging because of microbial growth limitations and the risk of toxins [27]. Numerous factors influence biogas production efficiency, including ambient temperature, pH, loading rate, and Hydraulic Retention Time (HRT). Additionally, the quantities of VFAs, ammonia, and sulfur play significant roles in the formation of biogas [28]. The pH significantly affects the development of microorganisms throughout the AD process. Studies have found that a neutral pH is optimal for producing large amounts of CH4, as most methanogenic microbes grow best in a pH range of 6.7–7.5 [29]. During AD, the methanogenic stage occurs at a pH range of 6.5–8.2, whereas hydrolysis and acidogenesis take place in more acidic conditions, with pH ranges of 5.5–6.5 [30]. D.H. Lee et al. [31] observed that methanogenesis could be effectively achieved at pH values ranging from 6.5 to 8.2. Protein disorders can lead to the accumulation of high ammonium concentrations in anaerobic microorganisms, which can be detrimental to AD [32]. Elevated ammonia levels can increase pH, creating a hostile environment for methanogens. This disrupts the balance necessary for efficient anaerobic digestion and reduces CH4 production [33].

The substrate type, toxicity, stirring, nutrients, slurry composition, plant construction, size, carbon-to-nitrogen ratio, alkalinity, initial feeding protocol, overall volatile acids, Chemical Oxygen Demand (COD), Total Solids (TS), and Volatile Solids (VS) influence the rate of biogas production [34]. In addition, the temperature within the biodigester plant significantly affects biogas generation [35].

Various pretreatment techniques have been developed to improve CH4 production by enhancing the AD of lignocellulosic substances in feedstock [36]. These techniques vary based on feedstock characteristics and operating conditions. Pretreatments can be classified into four main types: physical, chemical, physicochemical, and biological [37]. Each method has its advantages, but no single approach is ideal for all types of feedstock [38]. The common goal of all pretreatment strategies is to boost biogas production and generate a nutrient-rich digestate for use as fertiliser. Batch, continuous, and semicontinuous systems are the primary feeding systems used in anaerobic biodigesters. Batch systems are simple and cost-effective, in which feedstock is added and left to decompose until biogas is produced; however, they have limited capacity. In contrast, continuous systems allow for steady biogas generation by continuously feeding new materials while discharging the digested residue at the same rate. However, continuous systems may face challenges such as VFA accumulation, which can inhibit digestion [14]. These systems can be further categorised into single- or multi-stage processes [39]. A semicontinuous system combines the advantages of both batch and continuous systems. Feedstock is added at regular intervals, typically daily or weekly, and a portion of the digestate is removed accordingly. This system facilitates more stable biogas production than batch systems, requiring less constant feeding than fully continuous systems. Semicontinuous systems are often preferred for small-to-medium-scale operations because they offer steady-state operations with a lower risk of VFA accumulation and process inhibition, making them more practical for farms or small biogas plants [40].

Despite its potential, the utilisation of biogas as an energy source remains limited, primarily because of institutional, technological, financial, societal, and environmental barriers [41]. Furthermore, biomass availability varies regionally, posing challenges for biogas production in areas with limited feedstock resources. Establishing a biogas plant requires a significant initial financial investment, and the lack of political support may hinder the advancement of biogas generation [42]. Reports in the literature clearly show an increase in CH4 concentration by applying manure to a fixed dome biodigester. Ajieh et al. [43] utilised fixed-dome co-digestion of cow dung waste and water hyacinth inside a biodigester for 21 days until reaching CH4 56.4%. Obileke et al. [44] reported that producing favourable biogas outcomes via an insulated fixed-dome underground biodigester helps offer a more consistent internal temperature. Other work pointed in the same direction; Oji Achuka et al. [45] compared a 32 L fixed-dome biodigester load with Cow Abdominal Waste (CAW) and Poultry Waste (PW) at an HRT of 30 days. The concentrations were 68.39%, 66.41%, and 57.74% for the highest CH4 yields underground with CAW, underground with 1 CAW:1 PW, and non-underground with CAW, respectively.

The digestate from anaerobic digesters can be used effectively and safely in agriculture, providing a sustainable alternative to conventional fertilisers. Using digestate as a fertiliser in agriculture can offer significant benefits such as nutrient-rich fertilisation, reduction of chemical fertilisers, and waste recycling [46].

This study aims to contribute to the development of a sustainable and renewable energy source by harnessing biogas produced from livestock manure in Saudi Arabia. We focused on the design, construction, and performance analysis of a novel anaerobic underground Fixed-Dome Reactor (GFDR) specifically tailored for this purpose. The GFDR is designed to enhance methane production while minimising environmental impacts, offering a potential solution for waste management and energy generation in the region. This study provides a comprehensive characterisation of the feedstock, a detailed analysis of the biodigester design and operation, and an assessment of the potential of the digestate as a biofertiliser. Furthermore, we explore the energy balance and economic feasibility of implementing similar biodigester systems in Saudi Arabia. Our research aligns with the Sustainable Development Goals (SDGs) by promoting a cleaner and more sustainable future through waste management and renewable energy production. A preliminary life-cycle assessment suggested that the GFDR system could significantly reduce greenhouse gas emissions, and future studies should delve deeper into quantifying energy savings and nutrient recycling.

2 Materials and methods

2.1 Case study

This study investigates the performance of an anaerobic underground fixed-dome reactor (GFDR) designed to enhance methane production from livestock manure. The GFDR was constructed and operated in Dahaban, Saudi Arabia, using a semi-continuous feeding system. The key components of the GFDR, feedstock composition, and the methodology for data collection and analysis are detailed in the following sections. Considering Saudi Arabia as the case study, it is necessary to briefly investigate its potential for biogas production. This includes exploring modern technology, the current state of exploration, and different types and sizes of biogas reactors. The GFDR was established at a farm in Dahaban, located in the western part of Saudi Arabia, northeast of Jeddah City. The geographical coordinates of the farm are latitude 21°57′12″ N and longitude 39°08′30″ E, as seen in Figure 1. Dahaban is an appropriate location for a biodigester reactor as it is primarily populated by farms and factories. Therefore, site selection depends on factors such as proximity to the feedstock source, accessibility, and safety regulations.

|

Fig. 1 Location of the study area. |

The climate of Jeddah is characterised by hot desert conditions. The city’s weather is characterised by consistently high temperatures, with the highest temperatures occurring during the summer months. The average annual temperature is approximately 33.0 °C. In May, Jeddah starts to transition into its summer heat, with average high temperatures ranging from 24 °C to 38 °C [47].

2.2 Fabrication of the anaerobic biodigester

The anaerobic biodigester system comprises several components: a feedstock inlet chamber, a digested compost chamber, a transition compartment, and a biodigestion chamber. A GFDR with a bulk size of 22 m3 was installed as an underground biodigester system. A plant fabricated from brick, cement, and High-Density Polyethylene (HDPE) was used in this study. The biodigestion chamber has a height of 3.3 m and a radius of 1.45 m, giving it a total volume of 22 m3, without continuous stirring to avoid frequent breakdowns. HDPE was chosen as the fermentation chamber because of its ability to withstand exposure to moisture, corrosive gases, and raw material digestion, and its effectiveness in preventing gas emissions. HDPE also maintains warmth and acts as a good insulator. It offers excellent airtightness, corrosion resistance, and ease of manufacturing and construction. Most importantly, these bacteria can endure adverse environmental conditions while preserving their anaerobic state [48]. Additional materials such as Teflon, Acrylonitrile Butadiene Styrene (ABS), and fibre-reinforced plastic were used for the structure of the fermentation and gas storage chambers. A resistant foam material covering all sides of the dome was designed to withstand severe climatic conditions and prevent gas leakage. All four stages of biogas production occur in the lower region of the biodigestion chamber, whereas gas storage occurs in the upper region. The feedstock inlet, trawere included to prevent over-pressurization compartment and digestate compost chambers were constructed from locally made bricks and cement mortar, which was a mixture of cement and sand. The dimensions of the feedstock chamber are 2.5 m in height and 1 m in width. The transition compartment, located between the biodigestion and digestate compost chambers, measures 3 m in height and 1.5 m in width, while the digested compost chamber measures 2.8 m in height and 1.9 m in width. The feedstock inlet chamber was connected to the biodigestion chamber through a 45 cm diameter PVC pipe set at a 35° angle to the vertical. The transition compartment is connected using a PVC pipe with a diameter of 60 cm. Figure 2 schematically illustrates the GFDR.

|

Fig. 2 Schematic of the GFDR showing key components: Fermentation chamber (1), feedstock inlet (2), gas storage chamber (3), gas hose (4), sensor box (5), transition compartment (6), digested compost chamber (7), and PVC gas balloon (8). |

The system begins with a fermentation chamber, where the organic material breaks down to produce biogas. The feedstock inlet introduces a slurry mixture into the chamber. Once generated, the biogas is stored in a gas storage chamber and transferred through a gas hose.

The transition compartment buffers the material flow and prevents blockage. The digested compost chamber facilitates the natural flow of digestate, while additional biogas storage is handled by a 1 m3 PVC gas balloon.

The entire biodigester was installed underground and was fully insulated, as shown in Figure 3. The materials used, such as HDPE and reinforced concrete, were selected for their durability, corrosion resistance, and insulation properties. The underground installation helps maintain a stable temperature within the reactor, minimising the impact of external temperature fluctuations.

|

Fig. 3 The design of the installed biodigester reactor. |

The GFDR was designed to optimise biogas production with reactor dimensions based on the anticipated feedstock volume and HRT. HDPE and reinforced concrete were selected for their durability, corrosion resistance, and insulation properties to ensure efficient AD. The shape of the reactor maximised contact between the feedstock and microbial populations for the effective breakdown of organic matter. The insulation maintained stable conditions essential for optimal performance in various climates. Safety features, such as pressure relief valves and gas monitoring systems, were included to prevent over-pressurisation.

The gas outlet system featured a 1/2-inch galvanized iron pipe integrated into the dome, which was linked to the gas collection bag via PVC pipes, serving as the main gas line. Valves were installed along the gas line to regulate the gas flow and ensure control over its distribution. In addition, a tube connected to the gas line served as an indicator of gas production, and another pipe was used for the combustion test.

Designed for easy access, the system allows routine maintenance and inspection, including testing the integrity of gas lines and valves to prevent leaks. This setup ensures a reliable and controlled biogas supply for cooking, heating, or electricity generation.

Overall, the gas outlet system was designed to ensure an efficient gas flow and safe operation.

2.3 Construction of control unit

A Gas Pressure Monitoring System (GPMS) was developed to monitor the operations and record data for the biogas digester. In this study, real-time data were collected using the Message-Queuing Telemetry Transport (MQTT) service provided by Adafruit IO, which is a lightweight messaging protocol designed for efficient device communication in environments with limited network resources. The GPMS includes sensors for detecting CH4 and CO2 gas voltage levels (up to 10,000 ppm), a pressure sensor, and a type K thermocouple for temperature measurements.

Table 1 presents the equipment used for measurements in the development of the biodigester.

Information on equipment used for measurements.

These components were housed in a sensor box installed in the biodigester, as shown in Figure 2, which contained a WiFi + Bluetooth development board for mobile monitoring, an expansion board, and a power supply module (HiLink AC DC-15M05C) to ensure continuous operation. All the sensors were enclosed in a waterproof box designed for this study, ensuring protection and reliable operation under varying environmental conditions, as shown in Figure 4.

|

Fig. 4 (a) View of the gas-pressure monitoring system and (b) Rear view of the control box within the waterproof housing. |

A ventilation test was conducted after the fabrication to verify that the biodigester was leak-free. Constructed in July 2023, the biodigester reactor was operated from August 2023 to June 2024. During this period, the system was monitored regularly to assess the efficiency of organic waste management and biogas production. The GFDR features an underground design that stabilizes temperature for consistent biogas production, while its gas storage system ensures a reliable energy supply. With low-cost construction and 22 m3 capacity, it offers an affordable, scalable solution for small-to-medium agricultural operations in regions with limited renewable energy access.

2.4 Sample collection, preparations, and biogas production

The feedstock used included a mix of manure from horses (60%), cows (20%), sheep (10%), and camels (10%). Fresh manure was collected from animal enclosures and stored in covered containers to prevent moisture loss and contamination. Before being fed into the biodigester, the manure was thoroughly mixed to ensure homogeneity. These were chosen because of the availability of these animals in the area and their additional benefits, such as reducing odours and pathogens, the ability to produce biogas, and minimising environmental damage caused by traditional manure disposal techniques. This selection is further supported by the literature, indicating that horse and cow manure typically generate higher biogas yields owing to their rich organic and volatile solid content, providing an optimal balance for methane production. The use of these raw materials in Saudi Arabia has enormous potential for supplying clean energy and reducing environmental impact. In addition to reducing waste volume, this approach contributes to a more sustainable energy matrix [49]. Moharir et al. [50] have compared cow dung and horse manure, demonstrating that horse manure generated substantially more biogas, with a total volume of 35,366.03 cm3 over a 14-day cycle. They highlighted horse manure as a promising biomass source for biofuel production. The manure was diluted with water at a ratio of 1:2; that is, 1 kg of manure was mixed with 2 L of water. An Organic Loading Rate (OLR) of 20.6 kg VS/m3 day was achieved by feeding the biodigester 500 kg of mixed manure and 1000 L of water daily. The OLR was chosen based on literature recommendations and previous studies on the AD of livestock manure. Jeppu et al.’s [51] study on the AD of cow dung found that a dilution ratio of 1:2 (cow dung to water) resulted in a higher biogas yield because of reduced inhibition issues. The selected OLR ensured a balance between substrate availability and microbial activity, promoting efficient biogas production while maintaining process stability. The daily feeding regime allows for a consistent supply of nutrients to microorganisms, enabling steady-state operation of the biodigester. The gas valve was left open on the first day of feeding to allow air to flow throughout. After the fourth day, biogas was collected and recorded. On the 14th day, a biogas sample was collected from the inside of a special cylinder using an air compressor and transported to the laboratory for analysis. These analyses are essential for optimising biogas production processes. Each sample was analysed in triplicate to ensure the reliability of the results, and statistical tests were applied to assess significant differences between the datasets, enhancing the robustness of our conclusions.

The pH was regularly measured to assess the performance and stability of the system. The temperature inside the biodigestion chamber was recorded twice daily using a thermocouple for accurate monitoring throughout the 14 days. Table 2 shows ambient and internal biodigester temperatures.

The ambient and internal biodigester temperatures (°C) over 14 days.

The operation, initiated in August 2023, was intended to optimise feedstock selection and increase biogas production. Consequently, the study was conducted semi-continuously over 14 days. Mixed manure feedstock consisting of sheep, cow, horse, and camel wastes was used because of its high potential to enhance biogas yield. The biodigester was supplied with a fresh mixture of feed and water every 24 h. All the data were recorded from 26 April to 9 May 2024.

2.5 Lab analysis

A sample of the feedstock mixture was analysed to evaluate the physicochemical characteristics of the livestock feedstock used in the reactor. Physical and chemical analyses of the collected samples were conducted in duplicate at the Pioneers Laboratory of Soil, Water, and Plants Analysis (Jeddah, Saudi Arabia). The properties of the feedstock determined included TS, VS, organic dry matter, Total Nitrogen (TN), ammonia, phosphorus, potassium, oil and grease, and pH. Analysing the digestate material during AD is a critical practice that verifies that the process runs efficiently, safely, and in an environmentally sustainable manner. Gas analysis was conducted in duplicate at Abdullah Hashim Industrial Gases & Equipment Co., Ltd. (Jubail, Saudi Arabia) using an AGILENT 7890 B Gas Chromatograph (GC) in conjunction with a residual gas analyser (RGA) 2 (SGC-JU-L-E/A 018). The reference number used for this analysis is GC-GN0022696.

3 Results and discussions

3.1 Physiochemical characteristics of feeds

The properties of the feed used for AD play a critical role in determining the efficiency and effectiveness of the biodigestion process. Table 3 shows the findings for these characteristics.

Properties of feeds that are essential to AD.

The following technique was used to analyse the characteristics of the substrates: VS measurement by burning at 550 °C (APHA 2540 E), which provided insights into the organic matter content of substrates [52]. This method, outlined in the APHA 2540 E standard, involves drying a substrate sample and subjecting it to high-temperature combustion, where the VS is vaporised and non-volatile solids are left behind [53]. Another technique was TS measurement via drying at 105 °C, as described in the EPA 1684 method. This approach involves the evaporation of the liquid portion of the sample, leaving behind the total solid content, which includes both organic and inorganic matter [54].

Total nitrogen in the sample was determined using the APHA-provided standard micro-Kjeldahl technique. This method involves digestion of the sample using a strong acid, converting all nitrogen forms into ammonium ions ( ), followed by distillation and titration of the released ammonia, which allows for quantification of the total nitrogen content [55]. The organic dry matter content of the samples was measured using the ASTM D2974-20 standard. This method involves drying a sample at a specific temperature and measuring the remaining organic matter content [56]. Ammonia was determined using EPA 1690, a colorimetric method that utilises phenol and hypochlorite to form a blue complex, which was quantified using a spectrophotometer [57]. Phosphorus and Potassium were analysed using X-ray Fluorescence spectroscopy, a non-destructive analytical technique that determines the elemental composition of a sample [58]. The oil and grease contents of the samples were determined using the APHA 9071 B method, which involves the extraction of lipophilic substances from the sample followed by quantification. Finally, the pH was measured using a pH meter.

), followed by distillation and titration of the released ammonia, which allows for quantification of the total nitrogen content [55]. The organic dry matter content of the samples was measured using the ASTM D2974-20 standard. This method involves drying a sample at a specific temperature and measuring the remaining organic matter content [56]. Ammonia was determined using EPA 1690, a colorimetric method that utilises phenol and hypochlorite to form a blue complex, which was quantified using a spectrophotometer [57]. Phosphorus and Potassium were analysed using X-ray Fluorescence spectroscopy, a non-destructive analytical technique that determines the elemental composition of a sample [58]. The oil and grease contents of the samples were determined using the APHA 9071 B method, which involves the extraction of lipophilic substances from the sample followed by quantification. Finally, the pH was measured using a pH meter.

The feedstock properties were analysed to show that they were well-suited for AD. The high TS and VS contents indicated a substantial amount of organic material for digestion. High-solid-content anaerobic biodigestion, also known as dry AD, efficiently treats organic waste with minimal addition of water [59]. Most Franca and Bassin [60] studies have found that dry and continuous digestion systems perform better for biogas generation in both mono- and co-digested AD systems. Furthermore, because of the reduced demand for digestate dewatering following treatment, these techniques have proven to be more efficient and cost-effective.

Adequate levels of nitrogen, phosphorus, and potassium are required for microbial growth and activity. The pH was near neutral, which is ideal for anaerobic processes. Relatively low oil and grease content minimises the risk of process inhibition. Overall, the feedstock characteristics suggest a high potential for efficient biogas production and nutrient recycling. This mixture contained a low quantity of ammonia, 368.60 mg/kg; it is highly unlikely that this level would inhibit CH4 production during AD. High levels of ammonia in animal waste can inhibit CH4 production during AD. This inhibition occurs because ammonia concentrations above certain thresholds are toxic to methanogens, which are the microorganisms responsible for producing CH4. Research indicates that ammonia concentrations above 1500 mg/L can inhibit biogas production, with severe inhibition typically observed at levels above 3000 mg/L [61].

3.2 Physiochemical characteristics of digestate

Physical and chemical analyses of the biodigester outlet provided a comprehensive overview of various parameters that indicate the quality and characteristics of the digestate. Table 4 summarises the key characteristics of the digestate.

Physical and chemical analysis of digestate.

The digestate obtained from the biodigester was analysed for nutrient content, including nitrogen, phosphorus, and potassium. These results indicate that the digestate is rich in essential plant nutrients, making it a valuable biofertiliser. The analysis revealed that the digestate contained high moisture and significant levels of nutrients, especially nitrogen and potassium, with a lower phosphorus content. This suggests that the fertiliser was tailored to provide substantial potassium, which is vital for crops such as fruits, vegetables, and root plants. Furthermore, low concentrations of harmful substances, such as free chlorine and hydrogen sulfide, enhance its potential as a valuable fertiliser and soil amendment. However, the digestate also had high oil and grease content, along with elevated Biological Oxygen Demand (BOD) and Chemical Oxygen Demand (COD) levels. As a result, this fertiliser is rich in organic content and beneficial for soil health, but requires careful management to avoid environmental issues such as soil clogging and water oxygen depletion.

The digestate was stored in covered tanks to prevent nutrient loss and odour emissions. Field trials assessing its effectiveness as a fertiliser for various crops have demonstrated improved soil fertility and higher crop yields than those of conventional fertilisers.

The use of digestate as a biofertiliser offers a sustainable solution for nutrient recycling and reduces dependence on synthetic fertilisers. Its characteristics make it suitable for agricultural use, provided that it is applied in a controlled manner to maximise benefits and minimise potential negative impacts.

3.3 Biogas production analysis

The biodigester was closely monitored for 8 months, and the feeding ratio was changed many times to obtain the best results. Throughout all feeding phases, the main component of the feeding mixture was horse waste (total average fraction 70%), which was co-digested with various animal wastes such as cows, sheep, and camels. The main objective of this study was to manufacture and investigate the performance of a biogas production reactor from livestock manure using an AD semi-continuous system for 14 days. After 14 days, feeding and production monitoring continued.

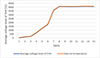

Table 5 shows the average voltage levels of the CH4 and CO2 produced inside the GFR.

The average quantity of CH4 and CO2 produced inside the biodigester.

The voltage level is not accurate and may be higher than the observed value because it has an upper limit of 10,000. However, a high voltage level indicated an increase in the gas percentage. The highest recorded CH4 and CO2 productivity were 4094.11 and 3417.08 on the 13th and 7th day, respectively. High CH4 voltage levels were recorded from day 7 of digestion to day 14, indicating that most of the feedstock was digested. From day 14 to day 20, the rate of productivity was considered stable with semi-continuous feeding; a very slight decrease in the voltage level does not mean that the production of CH4 has decreased because these values are average readings over an entire day. After 14 days, feeding was continued daily to maintain a steady state. Utilising a mixture of livestock waste is effective for biogas production. This is because the system is naturally stable owing to its high buffering capacity and sufficient trace-element content. Additional interventions are not required to maintain optimal conditions. Specifically, there was no need to actively adjust the pH or add additional trace metals to the biodigester [62].

The CH4 and CO2 contents were 56.40% and 34.80%, respectively, with an uncertainty of 2%. The biogas composition was analysed using Gas Chromatography (GC) following standard protocols. These concentrations are within the typical ranges reported for biogas produced from livestock manure. Trace amounts of other gases, such as hydrogen sulfide and nitrogen, were also detected. The specific biogas yield, calculated based on the volume of biogas produced per unit mass of feedstock, was found to be 0.35 m3/kg VS. This yield is comparable to values reported in the literature for similar feedstocks and biodigester configurations. Angelidaki and Ellegaard [63] discuss CH4 yields and biogas composition from co-digestion with various feedstocks, reporting values consistent with 56.40% CH4 and around 0.35 m3/kg VS yields. Table 6 shows a comparison analysis of key parameters for GFDR, Anaerobic High-Solid Treatment (HST), and Continuous Stirred Tank Reactor (CSTR) biogas production.

Comparison analysis of key parameters for GFDR, HST, and CSTR reactors for biogas production.

The methane content achieved with GFDR was found to be 56.40% compared to 58% in the case of HST and 51.4% for CSTR systems. This demonstrates that the GFDR system’s methane yield is comparable to that of HST, which operates at a larger scale, while surpassing the methane content achieved by the CSTR system. The higher methane concentration in the GFDR suggests its superior efficiency in methane recovery, particularly when utilizing livestock manure as the primary feedstock. Figure 5 shows the average CH4 and CO2 voltage levels obtained by GPMS during the 20 days of digestion.

|

Fig. 5 The average voltage level of gas produced inside the biodigester. |

Higher ambient temperatures within the mesophilic or thermophilic ranges generally lead to higher biogas production rates owing to increased microbial and enzyme activities. However, the actual temperature inside a biodigester can be influenced by ambient conditions. Nekhubvi and Tinarwo [66] concluded the effect of ambient air temperature on bio-slurry temperature; by using mathematical analysis, they showed a strong correlation between the biofeed temperature inside the biodigester and ambient temperature. They also found that as the temperature increased, the production rate increased. Sudiartha et al. [67] emphasized the importance of temperature management in anaerobic digestion. Temperature shifts, especially increases, can significantly disrupt biogas production. They highlighted how temperature (from 42 °C to 45 °C and beyond) led to substantial decreases in methane production, due to the impact on key methane-producing microbes. This study demonstrates the relationship between the internal temperature of the biodigester and the amount of CH4 produced. During 14 days, the internal temperature of the biodigester was observed to range between 35 and 37 °C. After the sixth day, the temperature stabilised at 35 °C, along with an increase in CH4 gas production. However, underground AD benefits from the Earth’s natural insulating properties, which help maintain a more stable internal temperature. This leads to more efficient digestion and higher biogas production. For instance, in colder climates, the reactor’s underground placement reduces heat loss, maintaining optimal operational temperatures for microbial activity. Similarly, variations in feedstock, such as high-fiber agricultural residues or food waste, may require adjustments in HRT and moisture content to prevent instability and optimize methane production. Future work will explore these adjustments, particularly in regions with diverse agricultural waste streams, to determine the most efficient operating conditions for the GFDR across different global climates. Figure 6 shows how internal temperature and CH4 production voltage are related.

|

Fig. 6 The relation between internal temperature and voltage level of CH4 production. |

Several adjustments were necessary during the experiments using the constructed biodigesters. These included adding insulation to the system to prevent air leakage after performing a leak test and changing the substance-to-water ratio to 1:2 to improve the performance.

The GPMS demonstrated that the data functioned within the required parameters, providing multiple readings per hour throughout the day, after being continuously connected to the Internet. However, further adjustments were required. Test experiments conducted on the final days showed that the system was working, although the readings, especially from the CO2 sensor, oscillated. These variations are likely due to electronic noise in the device. Future research should investigate the use of more accurate sensors and gas meters to improve the accuracy of the data collection and analysis. The solution to this issue involves implementing an advanced sensor and using a gas meter to calculate the specific biogas yield. However, such improvements incur additional costs.

Despite these challenges, the construction materials for the biodigester were effective and suitable for AD. In addition, GPMS successfully allowed continuous monitoring of the internal temperature and gas voltage levels. The gas sensors effectively detected voltage changes corresponding to CH4 and CO2 concentrations, demonstrating the system’s efficiency and affordability for data collection and management throughout the study.

De Souza Guimarães and da Silva Maia [68] noticed that a semi-continuous system demonstrated greater efficiency than a batch system in removing organic matter, producing biogas volume, and increasing CH4 percentage.

The energy management assistance program in Southeast Asia conducted research and found that 14 kg of cow waste and 0.06 L of diesel fuel may create 1 kWh of electricity [69]. However, CH4 content in the biogas produced was measured at 36 MJ/m3, representing its Lower Heating Value (LHV). This means that for each cubic meter of methane, 36 MJ of energy can be harnessed. The average CH4 concentration in the biogas was 56.40%, allowing for energy content calculations across varying CH4 concentrations.

At the lower bound (54.40% CH4), the biogas had an energy content of 19.584 MJ/m3, equating to approximately 5.44 kWh/m3 of electricity. At the upper bound (58.40% CH4), the energy content increased to 21.024 MJ/m3, corresponding to 5.84 kWh/m3. These results confirmed the success of biogas production, demonstrating that the system is highly productive and serves as a reliable energy source for electricity generation.

Throughout the 14-day experiment, the biodigester’s biogas production volume indicated that the selected feedstock was highly suitable for electricity generation. With an energy content of 5.646 kWh/m3, biogas also shows promise as a viable option for transportation fuel when upgraded to biomethane and compressed. Upgraded biomethane, with a high CH4 concentration, is a sustainable and clean alternative to conventional fossil fuels. When compressed, its enhanced energy density makes it well-suited for transportation, offering numerous environmental, economic, and technical benefits for a more sustainable energy landscape [70].

Following the GFDR experiment, it was observed that the GFDR achieved good efficiency in CH4 production. The gas behaviour (CH4 and CO2) followed a natural progression, with high initial CO2 production during the acetogenesis phase, which gradually decreased as CH4 levels increased. This was accompanied by stable temperature conditions within the biodigester, which further supported the efficiency of the system.

This study contributes to the field of anaerobic digestion by introducing a novel underground fixed-dome reactor (GFDR) design that is specifically tailored for small-to-medium-scale agricultural operations. The reactor’s ability to optimize methane recovery from livestock manure while also producing nutrient-rich digestate for use as biofertilizer presents a significant advancement in sustainable waste-to-energy (WTE) systems. Furthermore, the economic feasibility of constructing a 22 m3 reactor shows that such systems could be a cost-effective solution for rural areas in developing countries, advancing the global adoption of renewable energy technologies.

3.4 Implementation and economic feasibility of AD system

Implementing an AD system in Saudi Arabia is technically feasible and holds considerable promise given the country’s agricultural waste, leftover biomass, and the government’s push towards renewable energy. However, their economic feasibility depends on careful planning, government support, and market dynamics.

In a comprehensive review, Mir et al. [71] studied the environmental and economic impacts of waste management practices in Saudi Arabia. They emphasised the importance of implementing WTE plants. They highlighted the potential of technologies such as gasification and AD for handling large amounts of organic waste produced in Saudi Arabia. Several researchers have developed models to assess the economic feasibility of plants in terms of financial viability. One study by Hadidi and Omer [72] analysed the economic and environmental benefits of WTE plants, focusing on cost indicators such as the net present value, internal rate of return, and levelised cost of electricity. They concluded that although the initial investment in WTE plants is high, the long-term benefits in terms of energy savings, reduced waste management costs, and environmental improvements make it a viable option for Saudi Arabia.

Biogas plants will assist in minimising the costs of solid waste management, in addition to being an environmentally responsible approach to handling waste. Sadiq et al. [73] revealed that the Saudi market has an enormous waste potential. Cost analysis of the expected biogas production revealed that revenue may be obtained rather than paying money to dispose of garbage. A preliminary cost analysis indicates that the capital costs for constructing a 22 m3 GFDR in Saudi Arabia, including materials, labour, and installation, would be approximately $50,000. The operational costs, including electricity, maintenance, and labour, are estimated to be $5000 per year. Potential revenue streams include the sale of biogas for electricity generation at an estimated price of $0.05 per kilowatt-hour. Additionally, the digestate can be sold as a biofertilizer for $10 per ton. A simple economic model, considering the payback period and net present value, suggests that the GFDR system could be financially viable with a payback period of 5 years. The findings of this study prove that the energy obtained from leftover biomass is highly feasible and cost-effective, although production systems are not yet ideal, with the need to develop sensor systems and improve substances to increase organic material hydrolysis and inert particulate digestion. Furthermore, developments in the production technology for biogas and syngas will lessen the requirements for gas cleaning and modification, thereby minimising the cost of the process.

Globally, AD systems have been widely implemented, especially in Europe, which has seen significant growth in AD facilities, with more than 20,000 full-scale plants operating by 2022 [74].

In Saudi Arabia, the suggested financial models demonstrate that developing a WTE system based on AD may fulfil a portion of the country’s energy demands, lower its carbon footprint, and increase the rate of return on investment. Thus, it is economically feasible and advantageous to produce energy from biomass waste for transportation, power, and heat generation. To fully realise its potential, this technology should be promoted in places where it is currently underutilised and widely embraced in those where it is already in use.

4 Conclusion

Finally, we draw attention to the purpose of the study in publishing the research outcomes. This project successfully constructed a 22 m3 HDPE biodigester, connected to a 10 m3 gasbag for gas storage. The feedstock consisted of 60% horse waste, 20% sheep and camel dung, and 20% cow manure sourced from a farm. The analysis revealed that CH4 constituted 56.40% of the biogas generated, whereas CO2 accounted for 34.80%. The GFDR produces significant amounts of energy and has the potential to become an excellent reactor for biogas production in the future, especially for small and medium enterprises or family businesses that may struggle to dispose of their residues and byproducts from both management and economic perspectives. A comparative analysis with similar studies from different climatic zones showed that our biogas yields were consistent with or exceeded those reported under comparable conditions, underscoring the efficacy of our reactor design and operational strategy.

These findings are promising but warrant further investigation to enhance CH4 production and optimise management parameters, particularly feed type and water content, which should be higher than those used in this study. Given the high solids content, increasing the water quantity is crucial for preventing process instability and methanogenesis inhibition. This research supports the advancement of the SDGs and the development of a bio-based economy, particularly in waste management. By focusing on efficient biogas production from organic waste, this study aims to harness biogas for electricity generation to provide a sustainable and renewable energy source. The successful implementation of the GFDR could offer green energy solutions for farms and factories.

References

- Igliński B., Kiełkowska U., Pietrzak M.B., Skrzatek M., Kumar G., Piechota G. (2023) The regional energy transformation in the context of renewable energy sources potential, Renew. Energy 218, 119246. https://doi.org/10.1016/j.renene.2023.119246. [Google Scholar]

- Wang X., Yan R., Zhao Y., Cheng S., Han Y., Yang S., Cai D., Mang H.P., Li Z. (2020) Biogas standard system in China, Renew. Energy 157, 1265–1273. https://doi.org/10.1016/J.RENENE.2020.05.064. [Google Scholar]

- Pilarski K., Pilarska A.A., Boniecki P., Niedbała G., Durczak K., Witaszek K., Mioduszewska N., Kowalik I. (2020) The efficiency of industrial and laboratory anaerobic digesters of organic substrates: The use of the biochemical methane potential correction coefficient, Energies 13, 5, 1280. [Google Scholar]

- Jain S. (2019) Global potential of biogas. [Google Scholar]

- Heerenklage J., Rechtenbach J., Atamaniuk I., Alassali A., Raga R., Koch K., Kuchta K. (2019) Development of a method to produce standardised and storable inocula for biomethane potential tests – preliminary steps, Renew. Energy 143, 753–761. https://doi.org/10.1016/J.RENENE.2019.05.037. [Google Scholar]

- Chandra R., Takeuchi H., Hasegawa T. (2012) Methane production from lignocellulosic agricultural crop wastes: A review in context to second generation of biofuel production, Renew. Sustain. Energy Rev. 16, 3, 1462–1476. https://doi.org/10.1016/J.RSER.2011.11.035. [Google Scholar]

- Nandi S., Ahmed S., Khurpade P.D. (2023) Chapter 5 – Anaerobic digestion of fruit and vegetable waste for biogas and other biofuels, in: Mandavgane S.A., Chakravarty I., Jaiswal A.K. (eds.), Fruit and Vegetable Waste Utilization and Sustainability, Academic Press, pp. 101–119. https://doi.org/10.1016/B978-0-323-91743-8.00007-1. [Google Scholar]

- Franchetti M. (2013) Economic and environmental analysis of four different configurations of anaerobic digestion for food waste to energy conversion using LCA for: a food service provider case study, J. Environ. Manage. 123, 42–48. https://doi.org/10.1016/J.JENVMAN.2013.03.003. [Google Scholar]

- Ullah Khan I., Hafiz Dzarfan Othman M., Hashim H., Matsuura T., Ismail A.F., Rezaei-DashtArzhandi M., Wan Azelee I. (2017) Biogas as a renewable energy fuel – a review of biogas upgrading, utilisation and storage, Energy Convers. Manage. 150, 277–294. https://doi.org/10.1016/j.enconman.2017.08.035. [Google Scholar]

- Yoro K.O., Daramola M.O. (2020) Chapter 1 – CO2 emission sources, greenhouse gases, and the global warming effect, in: Rahimpour M.R., Farsi M., Makarem M.A. (eds), Advances in carbon capture, Woodhead Publishing, pp. 3–28. https://doi.org/10.1016/B978-0-12-819657-1.00001-3. [Google Scholar]

- Ignatowicz K., Filipczak G., Dybek B., Wałowski G. (2023) Biogas production depending on the substrate used: a review and evaluation study – European examples, Energies 16, 2, 798. https://doi.org/10.3390/en16020798. [Google Scholar]

- Dolganyuk V., Belova D., Babich O., Prosekov A., Ivanova S., Katserov D., Patyukov N., Sukhikh S. (2020) Microalgae: a promising source of valuable bioproducts, Biomolecules 10, 8, 1153. https://doi.org/10.3390/biom10081153. [Google Scholar]

- Ajibola H., Junior J., Haruna I. (2013) Development of anaerobic digester for the production of biogas using poultry and cattle dung: a case study of federal university of technology Minna cattle & poultry pen, Int. J. Life Sci 2, 3, 139–149. https://www.crdeep.com. [Google Scholar]

- Banerjee S., Prasad N., Selvaraju S. (2021) Reactor design for biogas production-a short review, J Energy Power Technol. 4, 1, 004. https://doi.org/10.21926/jept.2201004. [Google Scholar]

- Thanarasu A., Periyasamy K., Subramanian S. (2022) An integrated anaerobic digestion and microbial electrolysis system for the enhancement of methane production from organic waste: Fundamentals, innovative design and scale-up deliberation, Chemosphere 287, 131886. https://doi.org/10.1016/J.CHEMOSPHERE.2021.131886. [Google Scholar]

- Bond T., Templeton M.R. (2011) History and future of domestic biogas plants in the developing world, Energy Sustain. Dev. 15, 4, 347–354. [Google Scholar]

- Bhat P.R., Chanakya H.N., Ravindranath N.H. (2001) Biogas plant dissemination: success story of Sirsi, India, Energy Sustain. Dev. 5, 1, 39–46. [Google Scholar]

- Perea-Moreno M.A., Samerón-Manzano E., Perea-Moreno A.J. (2019) Biomass as renewable energy: worldwide research trends, Sustainability (Switzerland) 11, 3, 863. https://doi.org/10.3390/su11030863. [Google Scholar]

- Sahota S., Shah G., Ghosh P., Kapoor R., Sengupta S., Singh P., Vijay V., Sahay A., Vijay V.K., Thakur I.S. (2018) Review of trends in biogas upgradation technologies and future perspectives, Bioresour. Technol. Rep. 1, 79–88. https://doi.org/10.1016/J.BITEB.2018.01.002. [CrossRef] [Google Scholar]

- Tomczak W., Gryta M., Grubecki I., Miłek J. (2023) Biogas production in AnMBRS via treatment of municipal and domestic wastewater: opportunities and fouling mitigation strategies, Appl. Sci. 13, 11, 6466. https://doi.org/10.3390/app13116466. [Google Scholar]

- Fry L.J., Merrill R., Merrill Y. (1973) Methane digesters for fuel gas and fertilizer with complete instruction for two working models, New Alchemy Institute. [Google Scholar]

- Haynes W.M. (2016) CRC handbook of chemistry and physics, CRC Press, https://doi.org/10.1201/9781315380476. [Google Scholar]

- Elmoutez S., Abushaban A., Necibi M.C., Sillanpää M., Liu J., Dhiba D., Chehbouni D., Taky M. (2023) Design and operational aspects of anaerobic membrane bioreactor for efficient wastewater treatment and biogas production, Environ. Chall. 10, 100671. https://doi.org/10.1016/J.ENVC.2022.100671. [Google Scholar]

- Madigan M., Martinko J., Parker J. (2000) Brock’s Biology of Microorganisms, 9th edn. Prentice Hall. [Google Scholar]

- Raskin L., Poulsen L.K., Noguera D.R., Rittmann B.E., Stahl D.A. (1994) Quantification of methanogenic groups in anaerobic biological reactors by oligonucleotide probe hybridization, Appl. Environ. Microbiol. 60, 4, 1241–1248. https://doi.org/10.1128/aem.60.4.1241-1248.1994. [Google Scholar]

- Micolucci F., Gottardo M., Bolzonella D., Pavan P., Majone M., Valentino F. (2020) Pilot-scale multi-purposes approach for volatile fatty acid production, hydrogen and methane from an automatic controlled anaerobic process, J. Cleaner Prod. 277, 124297. https://doi.org/10.1016/J.JCLEPRO.2020.124297. [Google Scholar]

- Batstone D.J., Keller J., Angelidaki I., Kalyuzhnyi S.V., Pavlostathis S.G., Rozzi A., Sanders W.T.M., Siegrist H., Vavilin V.A. (2002) The IWA Anaerobic Digestion Model No 1 (ADM1), Water Sci. Technol. 45, 10, 65–73. [Google Scholar]

- Ali A., Mahar R.B., Panhwar S., Keerio H.A., Khokhar N.H., Suja F., Rundong L. (2022) Generation of green renewable energy through anaerobic digestion technology (ADT): technical insights review, Waste Biomass Valorization 14, 663–686. https://doi.org/10.1007/s12649-022-02001-7. [Google Scholar]

- Mata-Alvarez J., Macé S., Llabrés P. (2000) Anaerobic digestion of organic solid wastes. An overview of research achievements and perspectives, Bioresour. Technol. 74, 1, 3–16. https://doi.org/10.1016/S0960-8524(00)00023-7. [Google Scholar]

- Khalid A., Arshad M., Anjum M., Mahmood T., Dawson L. (2011) The anaerobic digestion of solid organic waste, Waste Manage. 31, 8, 1737–1744. https://doi.org/10.1016/J.WASMAN.2011.03.021. [Google Scholar]

- Lee D.H., Behera S.K., Kim J.W., Park H.S. (2009) Methane production potential of leachate generated from Korean food waste recycling facilities: a lab-scale study, Waste Manage. 29, 2, 876–882. https://doi.org/10.1016/J.WASMAN.2008.06.033. [Google Scholar]

- Jiang Y., McAdam E., Zhang Y., Heaven S., Banks C., Longhurst P. (2019) Ammonia inhibition and toxicity in anaerobic digestion: a critical review, J. Water Process Eng. 32, 100899. https://doi.org/10.1016/J.JWPE.2019.100899. [Google Scholar]

- Sihlangu E., Luseba D., Regnier T., Magama P., Chiyanzu I., Nephawe K.A. (2024) Investigating methane, carbon dioxide, ammonia, and hydrogen sulphide content in agricultural waste during biogas production, Sustainability 16, 12, 5145. https://doi.org/10.3390/su16125145. [Google Scholar]

- Sagagi B.S., Garba B., Usman N.S. (2009) Studies on biogas production from fruits and vegetable waste, Bayero J. Pure Appl. Sci. 2, 1, 115–118. https//doi.org/10.4314/bajopas.v2i1.58513. [Google Scholar]

- Abdelsalam E., Samer M., Attia Y.A., Abdel-Hadi M.A., Hassan H.E., Badr H.E. (2016) Comparison of nanoparticles effects on biogas and methane production from anaerobic digestion of cattle dung slurry, Renew. Energy 87, 592–598. https://doi.org/10.1016/J.RENENE.2015.10.053. [Google Scholar]

- Orlando M.Q., Borja V.M. (2020) Pretreatment of animal manure biomass to improve biogas production: a review, Energies 13, 14, 3573. https://doi.org/10.3390/en13143573. [Google Scholar]

- Bridgwater T. (2006) Biomass for energy, J. Sci. Food Agric. 86, 12, 1755–1768. https://doi.org/10.1002/jsfa.2605. [Google Scholar]

- Agbor V.B., Cicek N., Sparling R., Berlin A., Levin D.B. (2011) Biomass pretreatment: Fundamentals toward application, Biotechnol. Adv. 29, 6, 675–685. https://doi.org/10.1016/J.BIOTECHADV.2011.05.005. [CrossRef] [Google Scholar]

- Sarker S., Lamb J.J., Hjelme D.R., Lien K.M. (2019) A review of the role of critical parameters in the design and operation of biogas production plants, Appl. Sci. 9, 9, 1915. https://doi.org/10.3390/app9091915. [Google Scholar]

- de Souza Guimarães C., da Silva Maia D.R. (2023) Development of anaerobic biodigester for the production of biogas used in semi-continuous system bioprocesses: an efficient alternative for co-digestion of low biodegradability biomass, Biomass (Switzerland) 3, 1, 18–30. https://doi.org/10.3390/biomass3010002. [Google Scholar]

- Nevzorova T., Kutcherov V. (2019) Barriers to the wider implementation of biogas as a source of energy: a state-of-the-art review, Energy Strat. Rev. 26, 100414. [Google Scholar]

- Kozłowski K., Pietrzykowski M., Czekała W., Dach J., Kowalczyk-Juśko A., Jóźwiakowski K., Brzoski M. (2019) Energetic and economic analysis of biogas plant with using the dairy industry waste, Energy 183, 1023–1031. [Google Scholar]

- Ajieh M.U., Ogbomida T.E., Onochie U.P., Akingba O., Kubeyinje B.F., Orerome O.R., Ogbonmwan S.M. (2020) Design and construction of fixed dome digester for biogas production using cow dung and water hyacinth, Afr. J. Environ. Sci. Technol. 14, 1, 15–25. https://doi.org/10.5897/ajest2019.2739. [Google Scholar]

- Obileke K., Mamphweli S., Meyer E.L., Makaka G., Nwokolo N., Onyeaka H. (2020) Comparative study on the performance of aboveground and underground fixed-dome biogas digesters, Chem. Eng. Technol. 43, 1, 68–74. https://doi.org/https://doi.org/10.1002/ceat.201900378. [Google Scholar]

- Oji Achuka N., Chukwuka Paul O., Chibundo Emmanuel C., Chukwuemeka I., Ginika Frances U., Emmanuel Amagu E., Augustine Dinobi O. (2023) Effect of ground insulation and feed stock on performance of fixed dome biogas digester, Agric. Eng. Int. 25, 2, 145–171. http://www.cigrjournal.org. [Google Scholar]

- Lee M.E., Steiman M.W., Angelo S.K.St. (2021) Biogas digestate as a renewable fertilizer: effects of digestate application on crop growth and nutrient composition, Renew. Agric. Food Syst. 36, 2, 173–181. https://doi.org/10.1017/S1742170520000186. [Google Scholar]

- Weather Atlas (n.d.) Jeddah weather in May, Saudi Arabia, Weather Atlas, Available at https://www.weather-atlas.com/en/saudi-arabia/jeddah-weather-may (January 25, 2024). [Google Scholar]

- Obileke K., Mamphweli S., Meyer E., Makaka G., Nwokolo N. (2020) Design and fabrication of a plastic biogas digester for the production of biogas from cow dung, J. Eng. 2020, 1–11. https://doi.org/10.1155/2020/1848714. [Google Scholar]

- Jiménez Vásquez A.F. (2023) Atlas del potencial técnico energético aprovechable por digestión anaerobia de la biomasa residual pecuaria para los subsectores porcícola y ganadería de leche especializada en el departamento de Antioquia, Master’s thesis. Universidad de Medellín, Facultad de Ingeniería, Maestría en Ingeniería Urbana. Available at https://repository.udem.edu.co/handle/11407/6604. [Google Scholar]

- Moharir S., Bondre A., Vaidya S., Patankar P., Kanaskar Y., Karne H. (2020) Comparative analysis of the amount of biogas produced by different cultures using the modified Gompertz model and logistic model, Eur. J. Sustain. Dev. Res. 4, 4, em0141. https://doi.org/10.29333/ejosdr/8550. [Google Scholar]

- Jeppu G.P., Janardhan J., Kaup S., Janardhanan A., Mohammed S., Acharya S. (2022) Effect of feed slurry dilution and total solids on specific biogas production by anaerobic digestion in batch and semi-batch reactors, J. Mater. Cycles Waste Manage. 24, 1, 97–110. https://doi.org/10.1007/s10163-021-01298-1. [Google Scholar]

- Srivastava A., Sharma V.P. (2021) Water quality monitoring and management: importance, applications, and analysis, Appl. Water Sci 1, 421–440. https://doi.org/10.1002/9781119725237.ch16. [Google Scholar]

- Erber D., Cammann K., Roth J. (1997) New universal quartz burner for decomposition of samples by the Wickbold combustion technique in determination of arsenic, antimony, selenium, mercury, and lead, J. AOAC Int. 80, 5, 1084–1090. https://doi.org/10.1093/jaoac/80.5.1084. [Google Scholar]

- Akhter S., Rather L.J., Ganie S.A., Dar O.A., Hassan Q.P. (2019) Recent advances in the processing of modern methods and techniques for textile effluent remediation – a review, in: Shabbir M. (ed), Textiles and clothing: environmental concerns and solutions, Scrivener Publishing LLC, pp. 225–290. https://doi.org/10.1002/9781119526599.ch10. [Google Scholar]

- Kramer T.A., Hill T.K., Beckley J. (2004) Disinfection and dewatering of wastewater solids by interstitial vapor generation, Water Environ. Res. 76, 7, 2664–2671. https://doi.org/10.1002/j.1554-7531.2004.tb00228.x. [Google Scholar]

- Long Y., Meng A., Chen S., Zhou H., Zhang Y., Li Q. (2017) Pyrolysis and combustion of typical wastes in a newly designed macro thermogravimetric analyzer: characteristics and simulation by model components, Energy Fuels 31, 7, 7582–7590. https://doi.org/10.1021/acs.energyfuels.7b00796. [Google Scholar]

- Di Palma L., Verdone N., Chianese A., Di Felice M., Merli C., Petrucci E., Veriani G. (2002) Treatment of wastewater with high inorganic salts content, Environ Eng. Sci. 19, 5, 329–339. https://doi.org/10.1089/10928750260418962. [Google Scholar]

- Guo J., Deng D., Wang D., Yu H., Shi W. (2019) Extended suspect screening strategy to identify characteristic toxicants in the discharge of a chemical industrial park based on toxicity to Daphnia magna, Sci. Total Environ. 650, 10–17. https://doi.org/10.1016/J.SCITOTENV.2018.08.215. [Google Scholar]

- Rocamora I., Wagland S.T., Villa R., Simpson E.W., Fernández O., Bajón-Fernández Y. (2020) Dry anaerobic digestion of organic waste: a review of operational parameters and their impact on process performance, Bioresour. Technol. 299, 122681. https://doi.org/10.1016/J.BIORTECH.2019.122681. [Google Scholar]

- Franca L.S., Bassin J.P. (2020) The role of dry anaerobic digestion in the treatment of the organic fraction of municipal solid waste: a systematic review, Biomass Bioenergy 143, 105866. https://doi.org/10.1016/J.BIOMBIOE.2020.105866. [Google Scholar]

- Li Y., Zhu J., Tang Y., Shi X., Anwar S., Wang J., Gao L., Zhang J. (2023) Impact of varying mass concentrations of ammonia nitrogen on biogas production and system stability of anaerobic fermentation, Agriculture (Switzerland) 13, 8, 1645. https://doi.org/10.3390/agriculture13081645. [Google Scholar]

- Kadam R., Jo S., Lee J., Khanthong K., Jang H., Park J. (2024) A review on the anaerobic co-digestion of livestock manures in the context of sustainable waste management, Energies 17, 3, 546. https://doi.org/10.3390/en17030546. [Google Scholar]

- Angelidaki I., Ellegaard L. (2003) Codigestion of manure and organic wastes in centralized biogas plants, Appl. Biochem. Biotechnol. 109, 1, 95–105. https://doi.org/10.1385/ABAB:109:1-3:95. [Google Scholar]

- Westerholm M., Liu T., Schnürer A. (2020) Comparative study of industrial-scale high-solid biogas production from food waste: process operation and microbiology, Bioresour. Technol. 304, 122981. https://doi.org/10.1016/J.BIORTECH.2020.122981. [Google Scholar]

- Samiotis G., Panou M., Tsioni V., Sfetsas T. (2025)The effect of feeding on microbiome and biogas composition in 2 anaerobic CSTR. 11. https://doi.org/10.1101/2025.02.07.637154. [Google Scholar]

- Nekhubvi V., Tinarwo D. (2022) Prediction of slurry operating temperature and biogas production rate using ambient temperature forecast as input parameter for underground brick-built biogas digesters, Cogent Eng. 9, 1, 2034375. https://doi.org/10.1080/23311916.2022.2034375. [Google Scholar]

- Sudiartha G.A.W., Imai T., Mamimin C., Reungsang A. (2023) Effects of temperature shifts on microbial communities and biogas production: an in-depth comparison, Fermentation 9, 7, 642. https://doi.org/10.3390/fermentation9070642. [Google Scholar]

- de Souza Guimarães C., da Silva Maia D.R. (2023) Development of anaerobic biodigester for the production of biogas used in semi-continuous system bioprocesses: an efficient alternative for co-digestion of low biodegradability biomass, Biomass (Switzerland) 3, 1, 18–30. https://doi.org/10.3390/biomass3010002. [Google Scholar]

- Prussi M., Padella M., Conton M., Postma E.D., Lonza L. (2019) Review of technologies for biomethane production and assessment of Eu transport share in 2030, J. Clean. Prod. 222, 565–572. https://doi.org/10.1016/J.JCLEPRO.2019.02.271. [Google Scholar]

- Arfan M., Wang Z., Soam S., Eriksson O. (2021) Biogas as a transport fuel – a system analysis of value chain development in a Swedish context, Sustainability (Switzerland) 13, 8, 4560. https://doi.org/10.3390/su13084560. [Google Scholar]

- Mir M.A., Chang S.K., Hefni D. (2024) A comprehensive review on challenges and choices of food waste in Saudi Arabia: exploring environmental and economic impacts, Environ. Syst. Res. 13, 1, 40. https://doi.org/10.1186/s40068-024-00364-5. [Google Scholar]

- Hadidi L.A., Omer M.M. (2017) A financial feasibility model of gasification and anaerobic digestion waste-to-energy (WTE) plants in Saudi Arabia, Waste Manage. 59, 90–101. https://doi.org/10.1016/J.WASMAN.2016.09.030. [Google Scholar]

- Sadiq M., Khan M., Kaneesamkandi Z. (2013) Biodegradable waste to biogas: renewable energy option for the Kingdom of Saudi Arabia, Int. J. Innov. Appl. Stud. 4, 1, 101–113. http://www.issr-journals.org/ijias/. [Google Scholar]

- Kusch-Brandt S., Heaven S., Banks C.J. (2023) Unlocking the full potential: new frontiers in anaerobic digestion (AD) processes, Processes 11, 6, 1669. https://doi.org/10.3390/pr11061669. [Google Scholar]

All Tables

Comparison analysis of key parameters for GFDR, HST, and CSTR reactors for biogas production.

All Figures

|

Fig. 1 Location of the study area. |

| In the text | |

|

Fig. 2 Schematic of the GFDR showing key components: Fermentation chamber (1), feedstock inlet (2), gas storage chamber (3), gas hose (4), sensor box (5), transition compartment (6), digested compost chamber (7), and PVC gas balloon (8). |

| In the text | |

|

Fig. 3 The design of the installed biodigester reactor. |

| In the text | |

|

Fig. 4 (a) View of the gas-pressure monitoring system and (b) Rear view of the control box within the waterproof housing. |

| In the text | |

|

Fig. 5 The average voltage level of gas produced inside the biodigester. |

| In the text | |

|

Fig. 6 The relation between internal temperature and voltage level of CH4 production. |

| In the text | |

Current usage metrics show cumulative count of Article Views (full-text article views including HTML views, PDF and ePub downloads, according to the available data) and Abstracts Views on Vision4Press platform.

Data correspond to usage on the plateform after 2015. The current usage metrics is available 48-96 hours after online publication and is updated daily on week days.

Initial download of the metrics may take a while.