| Issue |

Sci. Tech. Energ. Transition

Volume 80, 2025

Innovative Strategies and Technologies for Sustainable Renewable Energy and Low-Carbon Development

|

|

|---|---|---|

| Article Number | 40 | |

| Number of page(s) | 10 | |

| DOI | https://doi.org/10.2516/stet/2025021 | |

| Published online | 03 June 2025 | |

Regular Article

A machine learning model for the computation of thermophysical properties of WCO biodiesel mixed with multiwalled carbon nanotubes

1

Department of Mechanical Engineering, SECAB Institute of Engineering and Technology, Vijaypur, Karnataka 586109, India

2

Department of Mechanical Engineering, Maulana Mukhtar Ahmad Nadvi Technical Campus, Malegaon, Maharashtra 423203, India

3

Department of Mechanical Engineering, Malla Reddy Engineering College, Maisammaguda (H), Medchal Mandal, Telangana 500100, India

* Corresponding author: syed.abbasali86@gmail.com

Received:

31

August

2024

Accepted:

6

May

2025

A Machine Learning (ML) model has been developed to compute the thermophysical properties of Waste Cooking Oil (WCO) biodiesel dispersed with MultiWalled Carbon NanoTubes (MWCNTs). The thermophysical properties when incorporating multiwalled CNTs into biodiesel are critical in improving performance, combustion, and emissions in internal combustion engines because of the high thermal conductivity and mechanical strength. Firstly, MWCNTs are mixed with WCO biodiesel for dosages of 30 ppm, 40 ppm, and 50 ppm. After it, each of the properties, including calorific value, density, viscosity, flash point, and fire point, is evaluated. Further, the MultiLayer Neural Network (MLNN) is a ML model that employs a back-propagation algorithm for mapping the input-output parameters. The parameters that constitute the input are WCO biodiesel blends and MWCNTs ppm. The parameters that are output include the calorific value, density, viscosity, flash point, and fire point. The optimum model’s results indicate that six hidden neurons (2_6H_5) can accurately predict the aforementioned properties under various operating conditions. Then, the Multivariable Regression (MVR) model has been devised to compare with the MLNN model. Subsequently, a comparison between the MLNN and MVR models has been carried out. The properties predicted by MLNN in comparison to the MVR model are seen as close to experimental values with good accuracy, as they depict the good “R” values as 0.98209, 0.97921, 0.99261, 0.9558, and 0.99139 for calorific value, density, viscosity, flash point, and fire point, respectively, and also give the average relative error (RE) for calorific value as 0.803%, density as 0.322%, viscosity as 3.036%, flash point as 5.104%, and fire point as 3.266%. Furthermore, the developed MLNN model is suitable for predicting the calorific value, density, viscosity, flash point, and fire point of WCO biodiesel that has been infused with MWCNTs. This saves time, money, and effort required.

Key words: Waste cooking oil / Multiwalled carbon nanotubes / Back propagation multilayer neural network

© The Author(s), published by EDP Sciences, 2025

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

1 Introduction

The thermophysical properties of biodiesel significantly influence its performance, fuel efficiency, combustion quality, and emissions in Internal Combustion (IC) engines [1, 2]. The impact of Lower calorific value reduces combustion duration, increases fuel consumption and emissions, and fuel atomization is impacted by higher viscosity and density, which results in incomplete combustion and higher emissions. Flash point and fire point mainly affect fuel handling and storage safety, and may contribute to cleaner combustion if properly atomized [1]. In recent advances, the nanomaterial-added fuel has been used for engines to perform well because of its better thermophysical properties over the long-established materials [2]. Some sorts of nanomaterials, such as SiO2 metal oxides [3] and the combined effect of TiO2 and hydrogen [4], have been looked into in a bid to find how well they can enhance the properties of biodiesel and the performance of the engine. The Taguchi technique has been proposed for biodiesel production dispersed with nanomaterial (K2CO3) in [5] and for thermophysical properties and fuel stability in [6]. In previous works, for the measurement of density, viscosity, and other properties of biodiesel, experimental examinations were accomplished by using standard set methods. Experimental investigations were carried out to change the properties of blended diesel-biodiesel [7]. The spectroscopic approach has been employed in blends to forecast the kinematic and dynamic viscosities [8]. Empirical methods and observations have been proposed for measuring and calculating the density and kinematic viscosity [9]. The various empirical relations developed to estimate the density-viscosity of the biodiesel blends for varying temperatures [10]. An assessment of the density and viscosity of binary blends has been conducted [11]. Diesel and fresh/waste vegetable oil blends were used in the investigation (empirical and experimental) of density, viscosity, sulfur content, and acid value [12]. The applications of various nanomaterials in various applications are given in [13, 14]. Different models have been developed to predict their physical properties, subsequently used for combustion simulation of CI engines [15]. The study related to experimental effort on the effect of different proportions of MgO in Waste Cooking Oil (WCO) biodiesel is seen in [16]. So far in the literature, investigation of fuel properties and engine parameters through experimentation and numerical/mathematical approaches has been used, which is neither cost-effective nor time-effective. Alternatively, Artificial Intelligence (AI) [17] and its subsets, Machine Learning (ML) [18], and Artificial Neural Networks (ANN) [19] models have been applied to IC engines. A review by [17] examined the AI and ML in optimizing biodiesel production processes and predicting fuel properties. The work focuses on developing ML models, viz., Support Vector Machine (SVM) regression, a burgeoning ML algorithm that predicts the fuel properties of the biodiesel produced from different feedstocks, including its calorific value, cetane number, and kinematic viscosity [18], and to predict iodine value in [20]. Discussion on ML algorithms to predict the thermophysical properties of hybrid nanofluids composed of Carbon NanoTubes (CNTs) and base fluids in [21]. The study presented in [22] various ML models to predict properties such as thermal conductivity, viscosity, and density of nanomaterial-dispersed biodiesel or other renewable energy fuels. Artificial neural networks and adaptive neuro-fuzzy inference systems approaches have been highlighted to predict thermophysical properties of biodiesel [23]. The waste management approach and ANN have been proposed for biodiesel production from catfish oil [24]. These models can be employed for the investigation of fuel properties that are associated with performance and emissions. This is because these models are more advantageous than other methods. Assessment of the relevance of ML and AI models for optimizing the efficiency of engines highlighted in [25]. In examination highlights the stability and thermophysical properties of MultiWalled Carbon Nanotubes (MWCNTs) coated with Fe3O4-fluids, while [26] develops a multilayer perceptron model. Up to the authors’ understanding, little work has been calling attention to the significance of MWCNTs in the WCO-biodiesel in diesel engines because WCO is regarded as an inexpensive biodiesel feedstock; its cost is much less than oil from other sources [27]. The prediction capability of a MultiLayer Neural Network (MLNN) to assess the emissions of diesel engine runs on low-cost biodiesel (WCO) dispersed with MWCNTs has been addressed in [28]. The literature appears to address the gap in thermophysical properties when incorporating CNTs into biodiesel, primarily because of the high thermal conductivity, mechanical strength of CNTs, which are critical in improving combustion, performance, and emissions in internal combustion engines [29]. Further, CNTs fill fuel, reducing the viscosity, which improves fuel atomization [30]. The comparative study of utilizing CNTs and metal oxides for the engine’s performance and emissions has been given in [31]. In addition, the ability of ML models, i.e., neural networks, to estimate/predict thermophysical properties of inexpensive biodiesel WCO mixed with MWCNT’s, needs to be examined in literature due to knowing that it is a universal approximator and is intended to be the best fit for modeling nonlinear, multivariable, and complex relationships [32, 33]. Eventually, the work in the present paper is accomplished to bridge the gap in the literature. Based on this, a ML-based MLNN has been designed to compute/predict the fuel properties, viz., viscosity, density, calorific value, flash point, and fire point of WCO biodiesel dispersed with MWCNT’s and following that, the Multivariable Regression (MVR) model has been devised to compare with the MLNN model. The novelty of developing a ML MLNN model for estimating the fuel properties lies in the MLNN approach, which contrasts with mathematical models. ML utilizes a wide variety of algorithms to find subtle links that may be missed by traditional approaches. The use of this cutting-edge method presents an opportunity to transform fuel optimization, resulting in a nanofuel that is effective and less harmful to the environment.

2 Experimental part

2.1 Procedure for dispersion of MWCNTs in WCO biodiesel

The study is interested in the preparation of WCO-biodiesel using a well-defined transesterification approach. The biodiesel blends have been prepared/produced as B10, B30, and B50, and then MWCNTs are added with the various fractions of 30 ppm, 40 ppm, and 50 ppm in WCO-biodiesel blends via an ultrasonicator. The nanotube fraction has been limited to 30–50 ppm. This is because increasing the concentration of nanotubes increases the density, viscosity, flash point, and fire point, but excess nanotubes can cause the engine to bang and become unstable, as well as decrease the calorific value, and increase the viscosity, flash point, and fire point [11].

Further, the nanomaterials required for addition are procured from “Platonic Nanotech Private Limited, Mahangama, India,” and MWCNTs standard characteristics are exhibited in Table 1.

The specifications of MWCNTs.

Several methods have been proposed to increase the uniformity of the mixture (nanotubes in biodiesel) [30]. The ultrasonic method may efficiently break down the MWCNT’s agglomerates, boosting the stability and the dispersion of MWCNTs in the fuel [28–30]. In the present study, an ultrasonication process is utilized to infuse the MWCNTs in the diesel and WCO biodiesel blend, wherein ultrasonic cavitation is usedto preserve homogeneity.

2.2 Experimental setup and the process for assessing the properties after the fuel mixture (diesel, biodiesel blend, and MWCNTs)

Further, the equipment used for the same is shown in Figure 1. Blends added with MWCNTs have been demonstrated to gather the values of calorific values (kJ/kg), density (kg/m3), viscosity (cSt), flash point (°C), and fire point (°C) via the instruments given in Figure 2. Bomb calorimeter (Fig. 1a) is used to measure calorific value, water is filled in calorimeter vessel and initial temperature of water is noted followed by ignition by pressing fire ignition button, water temperature readings are observed till it reaches maximum value. The density and viscosity of the sample are determined by using a digital weighing balance machine and viscometer; density is noted via a digital weighing balance machine by taking a specific volume of a given sample by weight. Viscosity can be assessed by observing the time for a specified volume of fuel to flow through an orifice at a controlled temperature, and flash point and fire point can be measured using Cleveland’s apparatus. The cup is packed with fuel to the mark, and electrical heat has been provided. Every 5–10 °C rise triggers a flash point test. The temperature at which fuel catches fire gives the flash point of the fuel. The fire point is computed by continuing to heat at the same pace. Take note of the temperature at which air-vapor gets ignited and continues to burn for a minimum time of five seconds till the test flame is brought close to it.

|

Fig 1 Equipment for dispersion of MWCNTs: a) Sonicator, b) Magnetic stirrer. |

|

Fig. 2 Equipment used for determining the properties: a) Bomb calorimeter, b) Digital weighing machine, c) Viscometer, d) Cleveland’s apparatus. |

2.3 Uncertainty of the outcome of experiments

To reduce the number of oversights that are associated with the instruments, an examination of the various parameters about the level of uncertainty has been carried out. The uncertainty of the instrument is determined by the operating and surrounding environmental factors, as well as the device’s accuracy. Multiple tests are run several times, and average values are used for later analysis (Table 2).

Uncertainty about experimental results.

3 Methodology

3.1 Machine learning model

Machine learning models comprise many simpler models predicting simple and linear relationships, some advanced architectures specialized for image-like data, and MLNN, etc. [32]. The MLNN is selected because it offers a balance between high predictive accuracy and flexibility, making it an ideal choice for biodiesel properties and engine parameters based on a variety of input features [25]. MLNN has been inspired by the working of the brain. The brain is highly complex, and it works differently from a conventional digital computer [32, 33]. It executes certain computations using neurons that are organized systematically. A developing neuron gathers information from its surroundings and learns to adapt to it. The most routine sort of neural network used is an MLNN with a single hidden layer. Figure 3 shows the MLNN with one hidden layer and an output layer. The “blends” and “PPM” are used as input variables because they significantly influence the overall characteristics of the biodiesel blend, and the output parameters considered are CV, density, viscosity, flash point, and fire point, as they affect more specifically the engine performance, combustion, and emission characteristics of IC engines [1, 28]. Two kinds of signals propagate in the network: Functional signals flowing in the forward direction and error signals flowing in the backward direction. Functional signals originate from the input layer and propagate forward through the network. The error signal propagates at the output layer and flows in the backward direction. The variables are depicted using one MLNN, and its output is denoted by equation (1)

![$$ P\left(\mathbf{w}\right)=f\enspace [{blends},\enspace {ppm},\enspace \mathbf{w}] $$](/articles/stet/full_html/2025/01/stet20240310/stet20240310-eq1.gif) (1)where the output of MLNN (predicted) is thermo-physical properties denoted as P(w), weights “w” and WCO-biodiesel blends, and MWCNTs ppm characterize the inputs of the system. The hyperbolic tangent and linear activation functions are described in equations (2) and (3) [32, 33]:

(1)where the output of MLNN (predicted) is thermo-physical properties denoted as P(w), weights “w” and WCO-biodiesel blends, and MWCNTs ppm characterize the inputs of the system. The hyperbolic tangent and linear activation functions are described in equations (2) and (3) [32, 33]: (2)

(2)

(3)where, v is neuron input.

(3)where, v is neuron input.

|

Fig. 3 The multilayer neural network. |

The inputs to the ML model MLNN are WCO-biodiesel blends and MWCNTs ppm. The weights are calculated by minimizing the cost function, ξ(w) given by equation (4): (4)where ε(w)2 is the error, calculated by

(4)where ε(w)2 is the error, calculated by  , P, and

, P, and  are the experimental and predicted properties, and N is the total number of training samples.

are the experimental and predicted properties, and N is the total number of training samples.

Arbitrarily dividing the data at network points into three groups, comprising 70%, 15%, and 15% of the total data, enhances the overall view. The early stopping method makes use of selecting the most suitable epoch (Fig. 4). Several structures of MLNN (from 2 to 14) are trained using MATLAB® 2014’s NN toolbox. To predict the parameter, the topology that provides the smallest average Mean Squared Error (MSE) for the validation data is chosen as the good topology (Table 3). The finest architectures, which have been found above, are utilized to estimate fuel properties at each given operating point of the engine. Further, the Hyperparameter details, dataset statistics, and cross-validation results are given in Table 4.

|

Fig. 4 Mean square error with respect to epoch number. |

The results of MLNN to compute the thermophysical properties.

Hyperparameter details, dataset statistics, and cross-validation results.

3.2 Multivariable regression model

A MVR model is a statistical technique used to understand the relationship between dependent variables and independent variables (predictors). The model has been implemented through MATLAB® 2014.

4 Results and discussions

4.1 Experimental findings of properties of diesel and MWCNTs dispersed WCO biodiesel blends

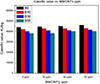

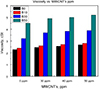

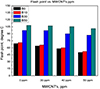

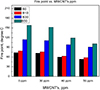

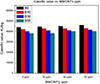

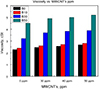

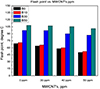

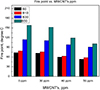

The MWCNTs added WCO-biodiesel blends and diesel properties for 0 ppm, 30 ppm, 40 ppm, and 50 ppm have been thoroughly explained. In Figure 5, the alterations in calorific value of varying blends with the change in MWCNT’s ppm are depicted and suggest that the calorific value is decreased as expected with the increase in the blend ratio, but with the increase in the inclusion of MWCNT’s, the CV is increased because of the higher carbon content in the MWCNTs [5, 7, 28]. Figure 6 indicates the increase in density with the increase in MWCNTs and the blend ratio. In MWCNT’s the carbon atoms are arranged in a dense thereby, they contributing additional mass to the mixture. Hence, a slight rise in the density at higher blends and MWCNT concentrations can be observed [8, 10]. Figure 7 discusses the effect on viscosity. The figure makes it quite evident that with the higher concentration of MWCNTs, there is a steep rise in the viscosity at any blend ratio because of the large aspect ratio (length to diameter) of MWCNT’s which contributes to the rise in the viscosity [8–11, 13]. The same trend is also seen in Figure 8 for the flash point. There is a rapid increase in the flash point with MWCNTs’ level at 40 and 50 ppm, contrary to the fire point being lowered in conjunction with the increase in blend ratio (Fig. 9). This is because of high surface area and thermal conductivity [7, 11, 28].

|

Fig. 5 Calorific value vs. MWCNTs ppm. |

|

Fig. 6 Density vs. MWCNTs ppm. |

|

Fig. 7 Viscosity vs. MWCNTs ppm. |

|

Fig. 8 Flash point vs. MWCNTs ppm. |

|

Fig. 9 Fire point vs. MWCNTs ppm. |

4.2 Discussion on the findings assessed through MLNN model and MVR model

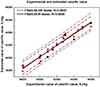

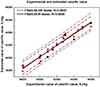

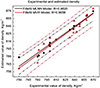

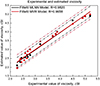

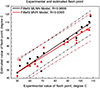

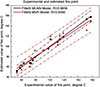

The results obtained with the MLNN model and MVR model to predict the thermophysical properties: calorific value, density, viscosity, flash point, and fire point of WCO-biodiesel mixed with MWCNTs are highlighted in this discussion. In this study, WCO-biodiesel was mixed with 30 ppm MWCNTs, 40 ppm MWCNTs, and 50 ppm MWCNTs. Further, the MLNN and MVR models were developed to predict the thermophysical properties, then regression analysis was employed to assess the models’ accuracy, and the correlation coefficient (R) is used as a measuring component in regression. The value of experimentation and predicted/computed properties is discussed for all the operating conditions. The experimental and computed/predicted thermophysical properties via MLNN and MVR models are shown in Figures 10–14.

|

Fig. 10 Experimental and estimated calorific value of MLNN and MVR model. |

|

Fig. 11 Experimental and estimated density of MLNN and MVR model. |

|

Fig. 12 Experimental and estimated viscosity of MLNN and MVR model. |

|

Fig. 13 Experimental and estimated flashpoints of MLNN and MVR model. |

|

Fig. 14 Experimental and estimated fire point of MLNN and MVR model. |

Figures 10–14 indicate that the MLNN model examined and demonstrated more accurately than the MVR model, as its “R” values are 0.98209, 0.97921, 0.99261, 0.9558, and 0.99139 for calorific value, density, viscosity, flash point, and fire point, respectively. The MLNN model is efficient in predicting the properties of WCO biodiesel dispersed with MWCNTs with acceptable accuracy. In addition, equation (5) depicts the relative error (RE). (5)

(5)

where Yexperimental is the experimental values and Ypredicted is the computed/predicted values. Thereafter, the average of all operating conditions is used as the value of RE. The MLNN and MVR models’ prediction ability is examined using RE(averaged) and R for all operating/test conditions. Further, to ascertain prediction uncertainty, a confidence interval (95%) is also shown in Figures 10–14.

4.3 Comparative study

A comparison of the MLNN model with the MVR model for predicting the thermophysical properties: calorific value, density, viscosity, flash point, and fire point of WCO-biodiesel mixed with MWCNT is presented in Table 5. Further, the regression analysis is employed to assess the accuracy of the models (MLNN model and MVR model), employing averaged RE and correlation coefficient (R) as measurement components in the regression. The results shown in Table 5 reveal that the MLNN model predicts thermophysical properties with greater accuracy than the MVR model, as reflected by its lower “RE”, and higher “R” values. However, the higher RE in predicting viscosity, flash point, and fire point using an MLNN and MVR model is likely due to the complexity and nonlinear behavior of these properties in response to variations in biodiesel blends and MWCNTs’ ppm, as well as measurement imperfections. Consequently, one may conclude that the MLNN model is better than the MVR model for the prediction of thermophysical properties.

Prediction ability of the MLNN model and the MVR model.

5 Conclusions

In this work, the evaluation of the thermo-physical properties of WCO biodiesel added with MWCNTs using a ML MLNN model and an MVR model has been done. MLNN’s optimum architecture, 3-6-5, is chosen for the model’s prediction over the entire operating/test conditions of the engine because it gives a Mean Square Error (MSE) equal to 0.1919. In addition to this, a comparison between the MLNN and MVR models has been carried out. The properties predicted by MLNN in comparison to the MVR model are seen as close to experimental values with greater accuracy, as they depict good RE(averaged) and R for all operating/test conditions. The RE (averaged) values for MLNN are as follows: calorific value is 0.803%, density is 0.322%, viscosity is 3.036%, flash point is 5.104%, and fire point is 3.266%. The ‘R’ values are also given in Figures 10–14, which for MLNN are found to be 0.98209, 0.97921, 0.99261, 0.9558, and 0.99139, respectively. The results show the values predicted by MLNN, and the experiments are reasonably close to each other. Given this, the utilization of MLNN over the MVR model is suitable for computing/predicting the calorific value, density, viscosity, flash point, and fire point of WCO biodiesel that has been infused with MWCNTs, which results in a reduction in the amount of time, money, and effort required.

Funding

The work presented in this manuscript has been supported by Vision Group on Science and Technology (VGST), Karnataka, India, under the “Research Grant for Scientist/Faculty (RGS/F)” scheme (GRDNo.980).

References

- Zhang Y., Zhong Y., Lu S., Zhang Z., Tan D. (2022) A comprehensive review of the properties, performance, combustion, and emissions of the diesel engine fueled with different generations of biodiesel, Processes 10, 1178. [CrossRef] [Google Scholar]

- Lv J., Wang S., Meng B. (2022) The effects of nano-additives added to diesel-biodiesel fuel blends on combustion and emission characteristics of diesel engine: a review, Energies 15, 3, 1032. [CrossRef] [Google Scholar]

- Rajeswari K.T., Selvadas S.S.R. (2023) Performance and emission characteristics of salviniaceae filiculoides aquatic fern oil and SiO2 nano additive biodiesel in CI engine, Sci. Tech. Energ. Transition 78, 4, 1–10. [CrossRef] [Google Scholar]

- Çalık A., Tosun E., Akar M.A., Özcanlı M. (2023) Combined effects of hydrogen and TiO2 nanoparticle additive on terebinth oil biodiesel operated diesel engine, Sci. Tech. Energ. Transition 78, 9. [CrossRef] [Google Scholar]

- Arita S., Komariah L.N., Andalia L.N., Hadiah F., Ramayanti C. (2023) Taguchi experiment design for DES K2CO3 glycerol performance in RBDPO transesterification, Emerg. Sci. J. 7, 3, 917–927. [CrossRef] [Google Scholar]

- Kota M., Madhavan V.R. (2024) Experimental and numerical analysis to enhance the thermodynamic properties and biofuel stability: Sapindus mukorossi, Energy Sources A Recovery Util. Environ. Eff. 46, 1, 13654–13666. [Google Scholar]

- Ali S.A., Hunagund S., Hussain S.S., Bagwan A.H. (2021) The effect of nanoparticles dispersed in waste cooking oil (WCO) biodiesel on thermal performance characteristics of VCR engine, Mater. Today Proc. 43, 888–891. [CrossRef] [Google Scholar]

- Zhang W., Yuan W., Zhang X., Coronado M. (2012) Predicting the dynamic and kinematic viscosities of biodiesel–diesel blends using mid- and near-infrared spectroscopy, Appl. Energy 98, 122–127. [CrossRef] [Google Scholar]

- Baroutian S., Shahbaz K., Mjalli F.S., Hashim M.A., AlNashef I.M. (2012) Densities and viscosities of binary blends of methyl esters + ethyl esters and ternary blends of methyl esters + ethyl esters + diesel fuel from T = (293.15 to 358.15) K, J. Chem. Eng. Data 57, 5, 1387–1395. [CrossRef] [Google Scholar]

- Gabriel R., Vieira W.T., Soletti J.I., Ribeiro L.M.O., Carvalho S.H.V. (2020) Empirical modeling of different viscosity and density behavior of biodiesel from chichá (Sterculia striata) with diesel versus temperature variation, J. King Saud Univ. Sci. 32, 1, 628–635. [CrossRef] [Google Scholar]

- Gulum M., Bilgin A. (2019) Measurement and prediction of density and viscosity of different diesel-vegetable oil binary blends, Environ. Climate Technol. 23, 1, 214–228. [CrossRef] [Google Scholar]

- Samuel O.D., Oreko B.U., Oyejide J.O., Idi S., Fayomi O.S.I. (2019) Experimental and empirical study of diesel and biodiesel produced from blend of fresh vegetable and waste vegetable oil on density, viscosity, sulphur content and acid value, J. Phy. Conf. Ser 1378, 4, 042024. [CrossRef] [Google Scholar]

- Arifin Z., Khairunisa N., Krishtiawan B., Prasetyo S.D., Bangun W. B. (2023) Performance analysis of nanofluid-based photovoltaic thermal collector with different convection cooling flow, Civ. Eng. J. 9, 8, 1922–1935. [CrossRef] [Google Scholar]

- Prasetyo S.D., Budiana E.P., Prabowo A.R., Arifin Z. (2023) Modeling finned thermal collector construction nanofluid-based Al2O3 to enhance photovoltaic performance, Civ. Eng. J. 9, 12, 2989–3007. [CrossRef] [Google Scholar]

- Bousbaa H., Kaid N., Alqahtani S., Maatki C., Naima K., Menni Y., Kolsi L. (2024) Prediction and simulation of biodiesel combustion in diesel engines: evaluating physicochemical properties, performance, and emissions, Fire 7, 364. [CrossRef] [Google Scholar]

- Ranjan A., Dawn S.S., Jayaprabakar J., Nirmala N., Saikiran K., Sriram S.S. (2018) Experimental investigation on effect of MgO nanoparticles on cold flow properties, performance, emission and combustion characteristics of waste cooking oil biodiesel, Fuel 220, 780–791. [CrossRef] [Google Scholar]

- Arif M., Alalawy A.I., Zheng Y., Koutb M., Kareri T., Salama E., Li X. (2024) Artificial intelligence and machine learning models application in biodiesel optimization process and fuel properties prediction, Sustain. Energy Technol. Assessments 73, 104097. [Google Scholar]

- Bukkarapu K.R., Krishnasamy A. (2024) Spectroscopy-based machine learning approach to predict engine fuel properties of biodiesel, SAE Int. J. Engines 17, 7, 871–881. [CrossRef] [Google Scholar]

- Bhatt A.N., Shrivastava N. (2021) Application of artificial neural network for internal combustion engines: a state of the art review, Arch. Comput. Methods Eng. 29, 2, 897–919. [Google Scholar]

- Valbuena G.D., Tuero A.G., Díez J., Rodríguez E., Battez A.H. (2024) Application of machine learning techniques to predict biodiesel iodine value, Energy 292, 130638. [CrossRef] [Google Scholar]

- Bhanuteja S., Srinivas V., Moorthy C.V.K.N.S.N., Kumar S.J., Raju B.L.L. (2023) Prediction of thermophysical properties of hybrid nanofluids using machine learning algorithms, Int. J. Interact. Des. Manuf. 18, 9, 6559–6572. [Google Scholar]

- Li N.H., Ali A., Hussein R.A., Singh N.S.S., Abdullaeva B., Ahmad Z., Salahshour S., Baghoolizadeh M., Pirmoradian M. (2025) Prediction of the thermophysical properties of Ag-reduced graphene oxide-water/ethylene-glycol hybrid nanofluids using different machine learning methods, Case Stud. Therm. Eng. 69, 106038. [CrossRef] [Google Scholar]

- Ude C.N., Onukwuli D.O., Okey-Onyesolu F.C., Nnaji P.C., Okoye C.C., Uwaleke C.C. (2022) Prediction of some thermo-physical properties of biodiesel using ANFIS and ANN cum sensitivity analysis, Clean. Waste Syst. 2, 100006. [CrossRef] [Google Scholar]

- Agu C.M., Ani K.A., Abiazieije P.O., Omeje J.A., Ekuma J.C., Umelo U.E., Omukwu O.H., Nwankwo E.D., Chinedu M.P. (2024) Biodiesel production from waste cat fish oil using heterogeneous catalyst from cat fish born: a viable waste management approach, and ANN modeling of biodiesel yield, Waste Manag. Bull. 1, 4, 172–181. [CrossRef] [Google Scholar]

- Soudagar M.E.M., Shelare S., Marghade D., Belkhode P., Nur-E-Alam M., Kiong T.S., Ramesh S., Rajabi A., Venu H., Khan T.M.Y., Mujtaba M., Shahapurkar K., Kalam M., Fattah I.M.R. (2024) Optimizing IC engine efficiency: a comprehensive review on biodiesel, nanofluid, and the role of artificial intelligence and machine learning, Energy Convers. Manag. 307, 118337. [CrossRef] [Google Scholar]

- Said Z., Sharma P., Sundar L.S., Afzal A., Li C. (2021) Synthesis, stability, thermophysical properties and AI approach for predictive modelling of Fe3O4 coated MWCNT hybrid nanofluids, J. Mol. Liq. 340, 117291. [CrossRef] [Google Scholar]

- Kulkarni M.G., Dalai A.K. (2006) Waste cooking oil – an economical source for biodiesel: a review, Ind. Eng. Chem. Res 45, 9, 2901–2913. [CrossRef] [Google Scholar]

- Hussain S.S., Ali S.A., Bagwan A.H., Husain D., Ahmad A. (2023) Prediction of CI Engine emissions fueled with multiwalled carbon nanotube-doped waste cooking oil biodiesel using multilayer neural network, J. Nanomater 2023, 1–9. [CrossRef] [Google Scholar]

- Hosseini S.H., Taghizadeh-Alisaraei A., Ghobadian B., Abbaszadeh-Mayvan A. (2017) Performance and emission characteristics of a CI engine fuelled with carbon nanotubes and diesel-biodiesel blends, Renew. Energy 111, 201–213. [CrossRef] [Google Scholar]

- Ruan B., Jacobi A.M. (2012) Ultrasonication effects on thermal and rheological properties of carbon nanotube suspensions, Nanoscale Res. Lett. 7, 1. [CrossRef] [Google Scholar]

- Zhang Z., Lu Y., Wang Y., Yu X., Smallbone A., Dong C., Roskilly A.P. (2019) Comparative study of using multi-wall carbon nanotube and two different sizes of cerium oxide nanopowders as fuel additives under various diesel engine conditions, Fuel 256, 115904. [CrossRef] [Google Scholar]

- Nørgaard M., Ravn O., Poulsen N.L., Hansen L.K. (2000) Neural networks for modelling and control of dynamic systems, Springer, London. ISBN 1-85233-227-1. [CrossRef] [Google Scholar]

- Haykins S. (2002) Neural networks: a comprehensive foundation, Pearson Education Inc, Singapore, ISBN 81-7808-300-0. [Google Scholar]

All Tables

All Figures

|

Fig 1 Equipment for dispersion of MWCNTs: a) Sonicator, b) Magnetic stirrer. |

| In the text | |

|

Fig. 2 Equipment used for determining the properties: a) Bomb calorimeter, b) Digital weighing machine, c) Viscometer, d) Cleveland’s apparatus. |

| In the text | |

|

Fig. 3 The multilayer neural network. |

| In the text | |

|

Fig. 4 Mean square error with respect to epoch number. |

| In the text | |

|

Fig. 5 Calorific value vs. MWCNTs ppm. |

| In the text | |

|

Fig. 6 Density vs. MWCNTs ppm. |

| In the text | |

|

Fig. 7 Viscosity vs. MWCNTs ppm. |

| In the text | |

|

Fig. 8 Flash point vs. MWCNTs ppm. |

| In the text | |

|

Fig. 9 Fire point vs. MWCNTs ppm. |

| In the text | |

|

Fig. 10 Experimental and estimated calorific value of MLNN and MVR model. |

| In the text | |

|

Fig. 11 Experimental and estimated density of MLNN and MVR model. |

| In the text | |

|

Fig. 12 Experimental and estimated viscosity of MLNN and MVR model. |

| In the text | |

|

Fig. 13 Experimental and estimated flashpoints of MLNN and MVR model. |

| In the text | |

|

Fig. 14 Experimental and estimated fire point of MLNN and MVR model. |

| In the text | |

Current usage metrics show cumulative count of Article Views (full-text article views including HTML views, PDF and ePub downloads, according to the available data) and Abstracts Views on Vision4Press platform.

Data correspond to usage on the plateform after 2015. The current usage metrics is available 48-96 hours after online publication and is updated daily on week days.

Initial download of the metrics may take a while.