| Issue |

Sci. Tech. Energ. Transition

Volume 78, 2023

|

|

|---|---|---|

| Article Number | 32 | |

| Number of page(s) | 60 | |

| DOI | https://doi.org/10.2516/stet/2023029 | |

| Published online | 28 November 2023 | |

Review Article

Literature review: state-of-the-art hydrogen storage technologies and Liquid Organic Hydrogen Carrier (LOHC) development

1

Univ. Grenoble Alpes, 38000 Grenoble, France

2

CEA, LITEN, DTNM, 38054 Grenoble, France

* Corresponding author: florian.dambra@posteo.net

Received:

10

March

2023

Accepted:

4

September

2023

Greenhouse gas anthropogenic emissions have triggered global warming with increasingly alarming consequences, motivating the development of carbon-free energy systems. Hydrogen is proposed as an environmentally benign energy vector to implement this strategy, but safe and efficient large-scale hydrogen storage technologies are still lacking to develop a competitive Hydrogen economy. LOHC (Liquid Organic Hydrogen Carrier) improves the storage and handling of hydrogen by covalently binding it to a liquid organic framework through catalytic exothermic hydrogenation and endothermic dehydrogenation reactions. LOHCs are oil-like materials that are compatible with the current oil and gas infrastructures. Nevertheless, their high dehydrogenation enthalpy, platinoid-based catalysts, and thermal stability are bottlenecks to the emergence of this technology. In this review, hydrogen storage technologies and in particular LOHC are presented. Moreover, potential reactivities to design innovative LOHC are discussed.

Key words: Hydrogen / Hydrogen storage / Liquid Organic Hydrogen Carrier (LOHC) / Hydrogenation / Dehydrogenation / Heterogeneous catalysis

© The Author(s), published by EDP Sciences, 2023

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

1 Introduction

Access and use of external energy have always been a preoccupation of human societies to facilitate the satisfaction of basic needs such as food cultivation/preparation, warmth production, or crafting of everyday materials. Our ancestors had simple energy forms at their disposal such as human muscle, animal muscle, burning of biomass, and renewable energy derived from the wind, water, and sun [1]. While used for tens of millennia, the development of stationary steam-powered engines supplied by fossil fuels in the late 18th century revolutionized the means of production. The development of new and more efficient processes like the replacement of wood for coal in the iron industry, deeper mining, or chemicals (especially sulphuric acid and sodium carbonate) durably modified Western societies, leading to the Industrial Revolution [2–6]. Since then, a strong increase in the global atmospheric concentrations of greenhouse gases such as carbon dioxide (CO2), methane (CH4), and nitrous oxide (N2O) was observed and their heat-trapping property started to abnormally modify the global climate, being later dubbed as climate change [7]. Over the past decades, this increase has been linked to anthropogenic emissions related to the combustion of fossil fuels (coal, oil, gas) for CO2 and agricultural malpractices for CH4 (manure and biomass burning) and N2O (synthetic inorganic fertilizers) [8–10]. As the effects of climate change are already visible and partially irreversible, the rapid reduction of greenhouse gases is a key target to limit the dire consequences on ecosystems, biodiversity, and human societies [11]. Under these circumstances, new carbon-free energy systems must be developed in order to simultaneously tackle the reduction of greenhouse gases and the access to energy for the already energy-lacking hundreds of millions in Africa, South America, and South–East Asia, while anticipating a global demographics increase [12].

Electricity is an energy sector where low-carbon alternatives such as nuclear power and renewable energies (namely solar power, wind power, hydropower, and geothermal power) are already implemented [13]. Low-carbon energies have gained traction over the last decades, earning from their much-added benefits to safety and direct CO2 emission reductions. The CO2 emission factor obtained by Life-Cycle Analysis for each power generation source without carbon capture is presented in Figure 1 [14, 15].

|

Figure 1 Direct and indirect CO2 emission factors for different types of power generation systems obtained by life-cycle analysis and adapted from [14, 15]. |

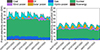

While the production of electricity can be attained by low-carbon technologies, it is important to note that 84% of the global primary energy production still came from fossil fuels in 2019 [1]. Hence a strong electrification of our societies is proposed to further the use of low-carbon technologies. As a consequence, the part of renewable energy sources has been steadily increasing from 14% to 22% in the French energy mix between 1990 and 2021, aiming for 32% in 2030 (Fig. 2) [16–18].

Although this energy transition has mainly consisted of reducing the part of nuclear power in the energy mix, new challenges are arising from this situation. Indeed, most of the prevalent renewable solutions (sun power, wind power, hydropower) are intermittent, i.e. they depend on the weather or a time cycle (day/night, seasonal, etc.) (Fig. 3) [19].

|

Figure 3 Energy production in France in January 2022 (left) and July 2022 (right), adapted from [20]. |

The energy variations due to the renewables are currently compensated by the pilotable energies (fossil fuels and nuclear). However, with their planned decrease in the energy mix, it will be progressively more and more difficult to adjust the production/consumption ratio and, in a hypothetical 100% renewables scenario, such a compensation mechanism would be strictly impossible. Moreover, excess energy produced by renewable sources during fast transitional regimes is currently discarded, leading to a net energy loss [20–22]. Hence, developing a technology to store the excess renewable energy for later use is key to removing pilotable fossil fuels from the energy mix and successfully abating greenhouse gas emissions. In addition, energy uncertainty management methods demand the dynamic integration of energy storage systems in the electric power distribution networks and the probable oversizing of the renewable power capacity [23, 24].

Thus, the design of smarter energy systems is sorely needed. An energy system is characterized by a succession of operations such as storage, transportation, conversion, and transformation of a set of energy resources to produce fine usable energy for a desired purpose (e.g. heat up our house). Following this example of our everyday life in a cradle-to-gate approach, an energy resource (for example coal) is extracted from the ground, then refined (conversion), stored, transported to a coal power plant, transformed into electricity which is then transported to our house before being converted to heat by a resistance in a heater (Fig. 4). It is worth noting that each step can produce waste and interact with the environment so limiting the number of steps usually is an efficient method to minimize adverse effects.

|

Figure 4 Example of an energy system to produce heat through a heater from coal. |

The transport and storage of energy are two essential steps for energy systems as energy is often produced remotely. Moreover, the need for instantaneous and continuous energy output requires additional energy to be stored in order to back up the energy systems in case of supply disruption. In our previous example, coal is a solid that can easily be stored and transported before use. However, swapping coal for renewable energy like solar power drastically changes our energy system as storing vast amounts of electricity becomes much more complex than a solid (Fig. 5).

|

Figure 5 Example of an energy system to produce heat from a heater from solar radiation. |

The concept of the energy vector answers this issue: the energy is converted into a new form that can be easily stored and transported. It is crucial to make a clear distinction between the primary energy source and the energy vector. In the energy system chain, a primary energy source such as fossil fuels, nuclear power, and renewable energies directly produces energy: this energy is readily available and will be lost if not used or stored otherwise. Primary energy resources can be separated into either renewable energy resources (solar radiation, water, biomass, wind, earth, sea, biological, and bacterial) that can be re-formed in the environment by natural processes or non-renewable resources (coal, oil, gas, and nuclear fuels) that cannot be regenerated by the environment in a period of time comparable to their use. Alternatively, a potential definition of an energy vector is human-made energy that is intended to replace a primary energy source at a required place and time [25]. In recent history, coal, oil and natural gas have been the go-to energy vectors backing up most of our energy systems. Other energy vectors include electricity, hydrogen (H2), synthetic fuels (methanol, ethanol, biodiesel, biogas, syngas), heat transfer fluids (low viscosity mineral oils), mechanical vectors (mechanical, oil-dynamic, and pressure-dynamic transmissions) and radiation. Each energy vector transports energy in a different form, either chemical, electric, thermal, mechanical, or radiative. In addition, energy vectors are not strictly replaceable with one another as each possesses its intrinsic limitations on its transportation and storage potential. A brief overview that does not take into account the storage efficiencies of the mentioned energy vectors’ transportation and storage capabilities is found in Figure 6.

|

Figure 6 Transport range and storage time of energy vectors. Electricity and radiation cannot be directly stored and thus are not included in the diagram. |

Among the energy vectors, H2 possesses a transport range and a storage time comparable to the currently employed fossil fuels depending on the employed storage technology. Mechanical systems based on physical phenomena such as compression used in Compressed Air Energy Storage (CAES) [26] or potential energy for Pumped Hydro Storage (PHS) [27] and heat exchange fluids can efficiently store energy, but their transportation properties of the stored energy are limited. Conversely, while electricity can be easily transported by the current power distribution network in the form of electrons, it can only be stored in limited amounts by supercapacitors with high self-discharging rates [28]. Hence conversion of electricity is usually needed to indirectly store it in electrochemical devices such as batteries (Li-ion, Pb acid, NaS, etc.) [29]. Finally, radiation such as light cannot be stored; it has however the theoretical highest transport range in vacuum, making it the best energy vector for interplanetary energy transfer [30].

2 Hydrogen as an energy vector

As presented in Figure 6, H2 presents transportation and storage properties similar to fossil fuels such as natural gas. Another interesting characteristic of H2 is its simple reactivity with O2 to yield only water and heat as products of the reaction, making it virtually an environment-friendly technology (1). (1)

(1)

Moreover, as seen previously, the implementation of intermittent renewable energies imposes the storage of large quantities of energy (in the TWh range) over a long duration (monthly to yearly) to cover seasonal variations. Fortunately, H2 possesses a high mass-energy density of 120 MJ/kg, about three times more than methane and other hydrocarbons [31, 32]. However, as H2 is a gas at normal temperature and pressure, it presents greater barriers to implementation compared to current liquid fuels: its density is minimal (0.09 g/L under normal conditions of temperature and pressure), leading to a necessary concentration of H2 in order to limit the size needed for storage [33]. Other characteristic disadvantages of H2 are its small size which facilitates its permeation out of containers, its embrittlement-inducing reactivity with common pipeline materials as steel, and potential ozone depletion if released in significant quantities [34–37].

Despite these limitations, H2 is globally considered an energy vector able to store vast amounts of energy over a long time scale that can be used as a secondary energy source for out-of-network applications and intercontinental storage and transportation energy systems. Promoted by newly implemented carbon regulations, H2 is becoming an opportunity to achieve a clean and secure energy future and its deployment is supported by different policies in various countries (Fig. 7) [38].

|

Figure 7 Number of policies around the world supporting hydrogen deployment, International Energy Agency, 2018 [38]. |

From this assessment, it is clear that building a hydrogen economy faces mainly financial and technological barriers. In order to boost its competitiveness, it is primordial to assess the key steps of the H2 economy value, namely its production and storage. In this review, the currently available H2 production technologies will be briefly covered before focusing on the available and in-development H2 storage technologies.

3 H2 generation

Except in some rare occurrences, pure H2 is unavailable in nature as it can break from Earth’s gravitational pull due to its low density and then leave the atmosphere when escaping from the underground [39–41]. Therefore, H2 needs to be produced from resources available in the environment. Current H2 production principally relies on converting non-renewable feedstock such as coal, Natural Gas (NG), and oil while only 5% is produced by renewable sources like water electrolysis and biomass [42, 43].

This section will review the different technologies available to produce H2 and their potential with regard to the energy transition.

3.1 Non-renewable H2 production (grey/brown hydrogen)

On the non-renewable side, three main reforming processes are currently employed to produce H2 and Carbon Monoxide (CO) from fossil carbonaceous substrates in the presence of a catalyst: Steam (Methane) Reforming (SMR), partial oxidation of hydrocarbons and autothermal reforming [44–47]. Further refinement of CO can be performed by the Water-Gas-Shift Reaction (WGSR) in order to produce a supplementary equivalent of H2 and CO2. Here, the main issues with these processes come from the concomitant production of CO2 as well as their high energetic cost due to the high pressure (up to 100 bar) and temperature (500–1500 °C) required for the reactions to occur. Although Carbon Capture and Sequestration (CCS) at the exhaust is getting more prominent, it does not intrinsically solve the thermodynamics issue and the efficient valorization of the CO2 is yet to be addressed [48]. More recently, hydrocarbon pyrolysis is being rapidly developed as it is in principle able to cleanly produce solid carbon and H2 at a reduced energy cost (38 kJ/molH2) compared to water electrolysis (285 kJ/molH2) (see Sect. 3.2) [49, 50]. As no CO2 is formed during the process and solid carbon can be valorized in different fields (e.g. soil enhancer), this technology is promising and companies like BASF are planning for industrialization in 2025 [51]. However, critics are also rising due to the use of methane (CH4) as hydrocarbon feedstock. Indeed, as CH4 emissions play a huge role in global warming, hydrocarbon pyrolysis would yield beneficial effects only if the global CH4 emissions diminish faster than the decarbonization of electricity [52]. Finally, all hydrocarbon-based processes are dependent on the quality of the feedstock. In particular, sulphur can poison the catalytic surfaces and react with H2 to form H2S, decreasing the purity of the gas and the overall efficiency of the reaction.

3.2 Water electrolysis (blue hydrogen)

Water electrolysis was discovered in 1789 by Jan Rudolph Deiman and Adriaan Paets van Troostwijk by producing electrostatic discharge between electrodes immersed in water [53]. While industrial interest sparked in the 1920s and 1930s, only recently has it been rediscovered as a convenient way to convert the intermittent electricity produced by renewable energies [54]. Water electrolysis is considered eco-friendly due to the lack of direct CO2 emissions in the process. However, the electric sources used to power the cell and the significant amount of required power play a huge role in the environmental impact of the process (hydro, wind, sun, nuclear versus gas, oil, coal) [42, 55]. As the price of renewable electricity is plummeting, decarbonization plans in Europe are promoting water electrolysis as the leading technology to produce renewable H2. In the wake of this trend, large-scale electrolysis facilities are being built around the world. The worldwide electrolyser capacity was 11 GW in 2022 with a possible installed capacity of 170–365 GW in 2030 if all of the planned projects are carried out. However, as an electrolysis capacity of 550 GW was envisioned by 2030 in the Net Zero Emissions scenario, a drastic increase of the electrolysis capacity installation is needed to achieve this target [56].

Water electrolysis is an umbrella term for different electrolysis technologies, namely alkaline [57], polymer electrolyte membrane technologies based on the transfer of protons (PEM) [58], or anions (AEM) [59] and Solid Oxide Electrolyte (SOE) [60]. On a general basis, these technologies are based on the application of an electric current to dissociate the atoms of H2O and then recombine them to form high-purity H2 and O2 (2). (2)

(2)

From a thermodynamic standpoint, this reaction is endothermic and nonspontaneous (see (1)). In standard conditions, a thermodynamic potential of 1.23 V is sufficient to produce H2. However, the irreversible energy costs associated with the operation of the electrolysis cell must be taken into account like the slow formation of O2 compared to H2 and ohmic losses due to resistances in each component of the circuit, in particular the resistance of the electrolyte. Therefore, the power-to-H2 efficiency depends on the employed technology: 60–70% for alkaline electrolysis, 60–80% for PEM electrolysis, and 40–60% for SOE electrolysis [61]. Nonetheless, with a supplied external heat of 150–180 °C to generate steam, up to 95% power-to-hydrogen efficiencies could be obtained for SOE electrolysis [62, 63]. Finally, alkaline and PEM electrolysis are currently the only commercially available technologies while SOE electrolysis is yet to be fully developed.

3.3 Renewable H2 generation (green H2)

Renewable sources of H2 can be separated into distinct classes as H2 can be obtained by transformation of a renewable resource by thermochemical or biological processes. It is worth noting that most renewable H2 sources can act as energy storage systems but of low capacity and/or only on a short-term basis.

Biomass usage possesses numerous beneficial environmental, social, and economic aspects such as the restoration of degraded lands, poverty reduction, and CO2 entrapment in carbon wells. Its conversion through various processes holds great promise for sustainable H2. Biological processes are based on anaerobic digestion [64] and fermentation followed by alcohol reforming [65, 66]. These technologies are promising but work only in optimal conditions and/or with little output. Other renewable H2 technologies revolve around biomass thermochemical processes such as pyrolysis [67], gasification [68], and supercritical water gasification [69]. As thermochemical processes are closer to the current industrial processes, they gather great interest. However, as numerous intermediate species can be produced, liquid and gas purification costs might be a major hurdle for these technologies.

3.4 Cost comparison of H2

The cost comparison of the different technologies used to produce H2 is presented in Figure 9 [70–79].

As numerous apparatus exist for each process, some variations in the hydrogen cost can be found for the same technology. Currently, the combined technologies SMR + WGSR without CCS are the cheapest energy source to industrially produce H2. However, H2 is nowadays proposed to store the excess of intermittent renewable energies. Currently, most of the produced H2 originates from the SMR + WGSR process and H2 produced from renewable is not competitive. Here, a decrease in the price of H2 generated from renewable energy is expected due to the massive implementation of renewables. Moreover, the SMR + WGSR process should be disfavored over time due to the emergence of new environmental legislation and the upsurge of global tensions.

Nevertheless, most techno-economic analysis in the literature limits their framework to the economic aspects of the technologies. To overcome this bias, a recent contribution from Al-Qahtani et al. suggests taking into account external factors in the price of H2 such as their costs on human health, ecosystem quality, and resource depletion by using life cycle monetization. The cheapest energy source for H2 production was still SMR + WGSR with direct carbon capture for 5 $/kgH2. Nevertheless, the most efficient energy sources with regard to the external factors were nuclear power, wind power, and solar power where 86%, 77%, and 86% respectively of the H2 cost was due to the selected technology [80]. The cost reduction of renewables and incentives should then play a key role in increasing their competitiveness for H2 production.

4 State-of-the-art hydrogen storage technologies

Once produced, H2 needs to be stored if not readily used. However, economic H2 storage is not straightforward due to its very low density: 11 m3 (size of the trunk of a big utility vehicle) would be required to store 1 kg of H2, whose energy is equivalent to driving a car for 100 km. Many H2 storage technologies aim at concentrating H2, based either on the physical properties of H2 (compressed gas (CGH2), cryogenic liquid (LH2) and Underground Storage Systems (UHS)) or on chemical properties of materials (physical adsorbents, metal hydrides, B–N H2 carriers, circular H2 carriers, and liquid organic H2 carriers) as presented in Figure 10.

|

Figure 10 Reviewed H2 storage technologies. |

Each technology will be briefly reviewed before focusing on Liquid Organic Hydrogen Carriers (LOHC) as well as other acceptorless hydrogenation and dehydrogenation reactions. Technologies can always be compared by the H2 weight storage density (wt.%H2) and the H2 volumetric storage density (gH2/L), but, depending on the encompassed element of the storage system, the said densities can be drastically modified. Here, we will only focus on the theoretical maxima of the hydrogenated species for chemical systems.

4.1 Physical-based hydrogen storage

Physical H2 storage technologies are based on controlling external parameters such as the pressure and temperature to concentrate H2, leaving the H2 molecule unmodified.

4.1.1 Compressed gas H2

Compressed gas H2 in steel cylinders is the most frequent H2 storage technology, storing 200 bar H2 (16.8 gH2/L, without the weight of the system). In theory, a continuous increase of the H2 pressure is the simplest way to improve the storage efficiency, providing that pressure-resistant materials are available. However, the H2 volumetric density is not linearly correlated with its pressure, and technical as well as economic restrictions limit the compression well below pressures equivalent to cryogenic H2 storage (2000 bar, 70 gH2/L, see 4.1.2) [81]. As a compromise between energy need and costs, the industry targets a pressure of 700 bar H2 with a total H2 and container system mass of 125 kg (including H2) using lightweight polymer fiber-reinforced vessels. Such systems could reach a weight density of 5 wt.%H2 and a volumetric density of 30 gH2/L, appropriate for personal vehicle transportation [82]. While this solution is practical and aimed at various fields such as heavy-duty transportation, it poses safety issues in case of violent breach of containment or uncontrolled H2 accumulation in an enclosed space like underground parking [83]. Finally, reaching a pressure of 700 bar of H2 has a non-negligible energy cost. In ideal isothermal conditions, 2.21 kWh/kgH2 is needed to compress H2 from atmospheric pressure to 700 bar. As the compression is not isothermal in real conditions due to self-heating upon applying pressure, the compression cost is significantly higher (up to 4 kWh/kgH2, more than 10% of the energy stored) [84, 85]. CGH2 presents numerous risks and limitations, but the relative simplicity of this technology explains its high prevalence for mobility applications.

4.1.2 Liquid H2 (LH2)

Hydrogen is a gas that reaches its liquefaction point at −252 °C, with a volumetric density of 70.8 gH2/L and a system weight density of up to 90 wt.%H2 depending on the container [86]. However, the liquefaction of H2 is not trivial due to its specific properties (inverse Joule-Thomson effect) [87]. Moreover, gas phase H2 is present in two forms depending on the nuclear spin alignment of its individual atoms (75% ortho) or not (25% para). Conversely, liquid phase H2 is stable at 99.8% in the para form, leading to the necessary conversion from ortho to para [87]. Unfortunately, this conversion is slow and exothermal (∆H = 525 kJ/kg), inducing an unavoidable evaporation of H2 (latent heat of vaporization = 476 kJ/kg), also called boil-off [88]. To facilitate this slow conversion during the cooling process, a catalyst is often integrated into the heat exchanger [89]. If this phenomenon is not accounted for, the pressure could drastically increase in a closed system, hence LH2 storage must be kept open to avoid disastrous events [90]. Open systems raise the question of efficient thermal insulation, with current systems losing roughly 1.5 wt.%H2/day. Finally, current industrial liquefaction plants consume between 13 and 15 kWh to produce 1 kg of LH2 (40–45% of the stored energy) and are not expected to drop below 5 kWh/kg LH2 (15% of the stored energy) [87]. Thus, the energetic cost of liquefaction is prohibitive for large-scale deployment and, while early projects targeted car mobility, LH2 will probably be used only for specific energy-intensive applications like rockets [91–93].

4.1.3 Underground H2 storage

Underground H2 storage is a potential large-scale mid to long-term stationary storage technology. Underground geological structures like empty gas or oil reservoirs, aquifers, and salt caverns can act as gas vessels to store pressurized pure H2 or a mixture of gases that contain H2. An appropriate UHS possesses a solid rock formation and an inert impermeable layer to prevent H2 leaks as H2 can slowly react with the minerals composing the UHS to form carbonates [94]. UHS also have to withstand an internal pressure of 30 to 80% of the lithostatic pressure in order to limit H2 leaks [95]. For the time being, only four artificial salt caverns are exploited worldwide [96]. For example, the most massive salt cavern (Spindletop, USA) occupies a volume of 906 000 m3 for a pressure reaching up to 200 bar (16.8 gH2/L) and could in theory store up to 500 GWh of H2, roughly 0.02% of the yearly French primary energy consumption in 2020 [97]. Salt caverns are the most efficient UHS, but represents only 8% of the worldwide capacity. Finally, while highly promising, UHS is especially sensitive to geological events like earthquakes, challenging to conceive/monitor, limited to specific geological conditions, and is in competition with other underground gas storage systems like CAES or CO2 storage.

4.2 Chemical-based hydrogen storage

The modification of the physical properties of H2 such as its temperature or pressure increases its energy density but requires a high energetic cost in order to reach efficient storage. A decrease of this energetic cost (equivalent to more than 10% of the energy stored for 700 bar CGH2 and between 40 to 45% for LH2) is necessary if H2 is to become a competitive energy vector. Hence finding new materials able to store H2 by forming bonds ranging from weak van der Waals interactions to covalent bonding has been an ongoing topic of research over the past decades. The main technologies of chemical-based storage will be reviewed hereinafter.

4.2.1 Physical sorbents

Physical sorbents can be compared to sponges for gaseous H2 where molecular H2 is adsorbed by physisorption on the surface of microporous materials by van der Waals interactions. H2 adsorption is usually carried out at a cryogenic temperature and high pressure (20–200 bar) for better performance. However, these materials must be kept at cryogenic temperatures and high pressures in order to be able to store high quantities of H2, increasing over time the energy cost of the storage. Moreover, the H2 intake is not linear with the increased pressure as strong adsorption is usually only observed at low pressures (up to a few bars) where capillarity or monolayer phenomena take place in the structure micropores. The intake increases slowly at higher pressures as all micropores are filled or multiple gas layers start to stack on top of each other, creating a non-adsorbed gas phase [98]. By heating up the material to room temperature or above, pure H2 can easily be released with only small amounts of H2 trapped in the structure. Finally, serious doubt has been cast on the validity of early results of physical sorbents for H2 storage. Indeed, the lack of reproducibility and high gravimetric H2 storage were linked to gas leaks and to the adsorption of molecules of higher molecular weight like water [99]. Current materials used for the physisorption of H2 are carbon nanomaterials (nanotubes, activated carbon, nanofibers, fullerenes, and so on), Polymers of Intrinsic Microporosity (PIM), Covalent-Organic Frameworks (COF), Metal-Organic Frameworks (MOF), zeolites, and water clathrates. The characteristics of each family of materials will be briefly described.

4.2.1.1 Carbon nanomaterials

Carbon Nanotubes (CNT), activated carbon, nanofibers, fullerenes, and graphenes are able to store H2, but this property is heavily dependent on their structure, geometry, operating temperature, pressure, and other parameters of the material. These materials possess multiple complex H2 adsorption sites that lead to extremely variable H2 capacity with a theoretic maximum of 10.8 wt.%H2 at 77 K and 60 bar [100]. However, it has been shown that the same material can produce inconsistent results. For example, a K-doped CNT was reported to store 1.8 wt.%H2 and 14 wt.%H2 in the same operating conditions [101, 102]. In addition, work by General Motors reveals that all H2 capacities above 1 wt.%H2 are probably due to experimental errors attributed to leaks [103]. Thus, the usual storage capacity at room temperature and high pressure is usually below 2 wt.%H2 [104]. Higher storage capacities can be reached when adsorption is conducted at cryogenic temperatures, with capacities of 6.5 wt.%H2 reported for activated carbon [105]. Chemisorption as π-bonding on aromatic cycles is also possible with extreme pressures (>500 bar) and high temperatures (500–600 K) treatments, adding one more H2 molecule per aromatic cycle [106]. Desorption happens around 400 K, but the extreme conditions for H2 chemisorption prevent it from being a viable H2 storage method [107].

4.2.1.2 Polymers of intrinsic microporosity

Microporous Polymers (PIM) are able to store H2 due to their rigid structure that forms interconnected cavities in the nanometer range, facilitating H2 adsorption [108]. Their intrinsic advantages are their easy customization by varying the monomer structure, their lightness, low cost, and simplicity of process. Nonetheless, they suffer from disadvantages similar to those of carbon nanomaterials as they require cryogenic temperatures and higher pressures to store relevant H2 amounts. Indeed, PIM can absorb up to 1.4 wt.%H2 at 1 bar and 77 K, increased to 1.7 wt.%H2 at 10 bar [109]. PIM showed improved properties when mixed with another physical sorbent, exhibiting up to 2.5 times more H2 adsorption, and is the current research focus for this technology [110].

4.2.1.3 Covalent-organic frameworks and metal-organic frameworks

Covalent-Organic Frameworks (COF) are rigid porous structures composed of organic molecules that are linked together by covalent bonds and are used for gas adsorption, separation, and catalysis like pesticide degradation [111, 112]. Due to their organic nature, COFs are extremely light, low cost, highly stable, and show great structure versatility in both 2D and 3D networks with different cavity sizes able to accept various molecules [113]. H2 adsorption in the structure can be achieved, usually at cryogenic temperatures (77 K) and at high pressures (20–100 bar). Temperature is the main factor contributing to their performance, as increasing the temperature above cryogenic levels drastically reduces their H2 adsorption capacity. To this date, a variation of the COF-102 showed very high gravimetric and volumetric densities of 25 wt.%H2 and 43 gH2/L at 77 K and 100 bar. However, room temperature H2 adsorption measurements on the same material exhibited reduced densities of 6 wt.%H2 and 10 gH2/L [114]. Doping the structure with metal ions was proposed in computational studies to improve the H2 capacity at room temperature, but no practical study has been reported so far [115].

Similar to COF, Metal-Organic Frameworks (MOF) are composed of metallic single atoms or clusters linked together by organic molecules, forming a porous crystalline structure able to adsorb H2 at cryogenic temperatures (77 K) and at high pressures (20–100 bar) depending on the cavity sizes and affinity with the metal and/or the organic linkers [116]. The current best H2 adsorption MOF is DUT-32 with a gravimetric density of 14.21 wt.%H2 at 77 K and 82 bar [117]. Addition of a metal catalyst in the structure and porous support like activated carbon could favor hydrogen spillover, where H2 is split into atoms and incorporated into the support, allowing for room-temperature H2 storage. While numerous publications reported a significant improvement of the hydrogen storage properties, spillover was heavily dependent on a number of inconsistent parameters, creating irreproducibility and even questions about the improvement of MOF by spillover [118–120].

4.2.1.4 Zeolites

Zeolites are crystalline materials defined by their network of pores that have been used for decades as sorbent materials and molecular sieves [121]. H2 adsorbing zeolites are composed of aluminosilicate porous structures with dimensions comparable to that of carbon nanotubes. Moreover, the charge of the framework is counterbalanced by metal cations that are readily exchangeable, which enables the tuning of the properties of the zeolite. H2 adsorption is believed to follow two mechanisms depending on the temperature. At high temperatures, encapsulation is the preferred mechanism: the openings of the zeolites are thermally activated which forces H2 adsorption in the structure, and the following cooling traps it [122, 123]. However, this mechanism does not substantially increase the amount of H2 stored in the structure as only a maximum of 0.8 wt.%H2 adsorption was reported [122]. At room temperature, the zeolite entrances were not activated, requiring high pressures to force H2 in the structure, leading to poor performances (<0.1 wt.%H2) [123, 124]. Better results were obtained when cooling the zeolite to cryogenic temperatures, with a maximum of 2.19 wt.%H2 for a CaX zeolite at 77 K and 15 bar [125]. Nevertheless, the theoretical maximum storage capacity was calculated to be less than 3 wt.%H2 which limits the efficiency of this storage technology [126].

4.2.1.5 Clathrates

Clathrates are supramolecular materials able to trap H2 in cavities formed by water molecules, without the formation of covalent bonds [127]. Pure H2-water clathrates can be formed and stabilized at cryogenic temperature (77 K) or extreme pressures (150 bar to 23 kbar reaching densities of 5.5 wt.%H2 and 45 gH2/L [128, 129]. The addition of a small amount of promoters like tetrahydrofuran (THF) stabilized the clathrates while limiting the temperature and pressure conditions for storage at the cost of an H2 storage capacity reduced to 1–2 wt.%H2 or less depending on the pressure [130]. Except for pure H2-water clathrates that are formed and stored in extreme conditions, the performance of hydrates clathrates does not deviate from other physical sorbents.

4.2.2 Metal hydrides/Interstitial hydrides

Metal hydrides are solid-state materials that attracted very early attention as a mean of hydrogen storage for individual transportation due to the reversible H2 absorption properties of metals M at high temperatures in less than an hour following the equation (3) [131]. The dehydrogenation reaction produces at the same time scale the original metallic phase and H2 with its kinetics being controlled by the temperature, pressure, and presence of a catalyst [132]. In addition, some Mg-based metal composite hydrides can be cycled up to 2000 cycles with good reversibility without major decrepitation due to the scaffolding effect of the composite [133]. (3)

(3)

In general, hydrides are heavy materials with low gravimetric and volumetric densities. Moreover, they are air- and water-sensitive (pyrophoricity) as oxygen tends to remove surface hydrogen to produce oxides, hydroxides, and carbon-oxygen compounds in the form of a surface passivation layer. Removal of this layer with H2 at high temperatures is necessary in order to increase the hydrogenation kinetics [134–136]. Sulphur compounds are also a common poison [137]. Finally, these materials consume a non-negligible amount of metals and their solid state complicates their handling from an industrial standpoint as their processing consumes more energy than liquids and can form reactive and hazardous dust.

Metal hydrides can be grouped into low-temperature hydrides, high-temperature hydrides, and complex hydrides depending on their desorption temperature and composition. A brief overview of the properties of each class of materials will be presented.

4.2.2.1 Low-temperature hydrides

Low-temperature metal hydrides, also known as intermetallic hydrides, can release H2 close to room temperature and atmospheric pressure, which is advantageous as almost no energy is required to harness H2 but also a drawback due to safety issues in case of undesired heating [138]. Intermetallic hydrides are synthesized from a mixture of high hydrogen affinity elements “A” like Ca, Sc, Y, Ti, Zr and other lanthanides and low-affinity elements “B” like Cr, Mn, Fe, Co or Ni that act as dissociation promoters to create ternary A x B y H n materials [139]. During the absorption, H2 is dissociated in H atoms on the surface and form covalent bonds before migrating in the bulk of the material by atomic diffusion to the interstitial sites of the lattice [134]. Therefore, the defined crystalline structures (AB5, AB2, A2B, …) play a primordial role in the H2 adsorbing properties as the size of their interstitial sites is phase-dependent [140]. However, due to their weight, the maximum energy density of intermetallic hydrides stays usually below 2 wt.%H2, far from the necessary 6 wt.%H2 for mobility applications according to the United States Department of Energy (DOE) [141, 142].

4.2.2.2 High-temperature hydrides

High-temperature metal hydrides require desorption temperatures above 200 °C to break the ionically bound hydrogen atoms. Most high-temperature hydrides are based on magnesium and its alloys due to its lightness, abundance, low cost, and good reversibility. The most studied one is MgH2, which possesses a high weight density of 7 wt.%H2. Unfortunately, this material requires a temperature of at least 300 °C to harness H2 due to its high stability, slow kinetics, and sensitivity to decrepitation [143, 144]. Alloys of high-temperature metal hydrides with transition metals like Ti, V, Mn, Ni, and Fe have shown improved thermodynamics, H2 uptake/release kinetics and stability by promoting the dissociation/recombination of H2 [145]. Nanostructuring the metal hydride is also a conventional technique to decrease the size of the metal clusters to the nanometer range in order to improve the thermal and mechanical stability, thermodynamics and kinetics [146–148]. Finally, akin to nanostructuring, nanoconfinement relies on the nano-scale properties of hollow light-weight nano-porous chemically inactive materials like carbon-based materials, mesoporous silica, zeolites, and MOFs to promote H2 physisorption, H2 dissociation, desorption thermodynamics, and kinetics as well as stability by limiting the agglomeration of the metal hydride nanoparticles [149–151].

4.2.2.3 Complex hydrides

Over the past two decades, complex hydrides containing only low molecular weight atoms have been heavily studied [152]. Compared to the desorption temperature of low-temperature metal hydrides (room temperature to 100 °C) and high-temperature metal hydrides (200–300 °C), their intermediate desorption temperature (100–200 °C) presents a good compromise between safety and energy efficiency. Such desorption temperatures are achieved by exploiting the versatile nature of the hydrogen atom that can act as both a cation H+ and an anion H−. Indeed, H2 is stored in complex hydrides by a mix of ionic and covalent bonds, usually forming tetrahedrons with boron or aluminum at the center and hydrogen atoms at the corners while the charge is balanced by one or more spectator cations like Li or Na. The dehydrogenation process is heavily dependent on the metallic center, however, it typically consists of the formation of a pure metallic phase and a cation-hydride phase, e.g. in the case of alanates (4): (4)

(4)

In general, complex hydrides are synthesized by mechano-chemistry like ball milling which limits their industrialization. In addition, they present a high chemical risk as they are highly reactive in the presence of water and must be used only in anhydrous conditions [153]. Moreover, reversibility can be limited due to the lack of hydrogen-deficient intermetallic compounds and the formation of multiple phases during the dehydrogenation [154]. Thus, efficient regeneration procedures are still in development to further develop this technology. Complex hydrides can be grouped depending on their metallic anion. Alanates like NaAlH4 [155, 156] (7.4 wt%H2 and 67 gH2/L) and borohydrides like LiBH4 [157] (18.5 wt.%H2 and 122 g H2/L) are the most studied complex hydrides, but new amide-hydride composites like Li(NH2)–2LiH [158] (10 wt.%H2 and 104 gH2/L) are presenting promising properties.

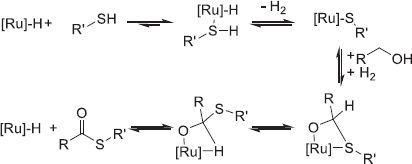

4.2.3 B–N H2 carriers

B–N hydrogen carriers are composed of two key atoms: boron which acts as a metallic center for hydrides and nitrogen for protons. Ammonia–borane (AB) was initially proposed as an alternative to borohydrides due to its high gravimetric and volumetric densities (19.4 wt.%H2 and 144 gH2/L, resp.) [159]. As AB is a solid, liquid phase dehydrogenation of AB is carried out in a protic solvent like water or methanol. However, this hydrolysis or alcoholysis induces the formation of oxidized dehydrogenated boron species that require a harsh regeneration with the extensive use of strong hydrides or other complex processes [160, 161]. The dehydrogenation of solid AB can be achieved by thermolysis. Heating up to 100 °C is sufficient to dehydrogenate AB to linear, branched, or cyclic polyaminoborane species depending on the reaction environment (5) [162]. Two other H2 equivalents can be produced when increasing the temperature to 120–130 °C and 500 °C in order to form polymeric borazine and Boron Nitride (BN) as presented in equations (6) and (7) respectively [163, 164].![$$ n\mathrm{B}{\mathrm{H}}_3-\mathrm{N}{\mathrm{H}}_3\to {\left[-\mathrm{B}{\mathrm{H}}_2-\mathrm{N}{\mathrm{H}}_2-\right]}_{\mathrm{n}}+n{\mathrm{H}}_2, $$](/articles/stet/full_html/2023/01/stet20230038/stet20230038-eq5.gif) (5)

(5)

![$$ {\left[-\mathrm{B}{\mathrm{H}}_2-\mathrm{N}{\mathrm{H}}_2-\right]}_n\to {\left[-\mathrm{B}{\mathrm{H}}_2=\mathrm{N}{\mathrm{H}}_2-\right]}_n+n{\mathrm{H}}_2, $$](/articles/stet/full_html/2023/01/stet20230038/stet20230038-eq6.gif) (6)

(6)

![$$ {\left[-\mathrm{B}{\mathrm{H}}_2=\mathrm{N}{\mathrm{H}}_2-\right]}_n\to {\left[\mathrm{BN}\right]}_n+n{\mathrm{H}}_2. $$](/articles/stet/full_html/2023/01/stet20230038/stet20230038-eq7.gif) (7)

(7)

As BN is a very stable chemical, the dehydrogenation is usually limited to the first two steps to ensure the regeneration of the material, diminishing the effective densities to 12.9 wt.%H2 and 96 gH2/L. In addition, side-products like ammonia and other boron and nitrogen-containing gaseous products have been reported in large quantities (>20 wt.% of the AB weight) due to AB decomposition [165]. However, as the mechanism of degradation is heavily dependent on the conditions of the reaction (solvent, solid-state, etc.), it is not yet fully elucidated. AB solubilization in an aprotic solvent like ionic liquids improved the dehydrogenation as the solvent disrupted the proton-hydride intramolecular bonding and limited the carrier oxidation [166]. Similarly, dopant addition diminished the induction period and increased the kinetics and selectivity of dehydrogenation [167]. Nanoconfinement of AB in a nanostructure acted in the same fashion as metal hydrides (see 4.2.2.2) [168]. Lastly, the incorporation of alkali, alkaline-earth, or metals (Al) to the AB structure created heavier amidoboranes, where the partial replacement of the protons by a more electropositive element increased the selectivity and dehydrogenation kinetics at the cost of a portion of the H2 capacity [169–171].

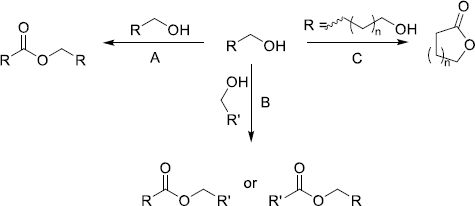

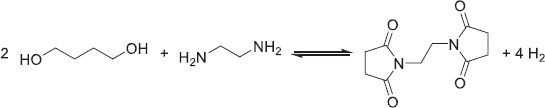

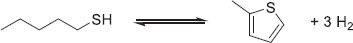

4.2.4 Circular hydrogen carriers

Circular hydrogen carriers store H2 through chemical bonds on small gaseous molecules like N2 or CO2 to form respectively ammonia (NH3) or methanol (MeOH) (Fig. 11). Other products like hydrazine, formic acid, formaldehyde, methane, dimethylethers, carbonates, or carbamates are also circular hydrogen carriers but they will not be discussed due to their comparatively low technological development.

The main advantage of circular H2 carriers is their convenient transportation properties that allow for the production of H2 at a place of convenience where the gaseous lean carrier can be captured before recycling. In addition, the hydrogenated carriers are also high-value chemicals that can directly be used in chemical processes but H2 will not be retrieved in that case. The main issue of this technology revolves around the necessary gas separation and purification of the lean carriers from H2 during dehydrogenation as well as large-scale gas handling.

4.2.4.1 Ammonia

Ammonia is a valuable chemical for the synthesis of fertilizers that can act as an energy vector able to store H2 in liquid form with good gravimetric (17.8 wt.%H2) and volumetric (107 gH2/L) densities when pressurized at 8.6 bar at room temperature. Current production is guaranteed by the Haber–Bosch process which produces roughly 185 million tons of NH3 per year in 2020 [173, 174].

-

Hydrogenation

NH3 is produced in extreme conditions of temperature and pressure from N2 and H2 with a low conversion of 15% per pass, thus requiring numerous cycles of the reactants to achieve complete conversion (8).

In addition, as presented previously (see Sect. 3), most of the currently produced H2 originates from fossil fuels. As a consequence, this industrial process consumes between 1 and 2% of the annual global energy production and generates 3 equivalents of CO2 per 8 equivalents of NH3 [175, 176]. Nevertheless, as this process is almost completely optimized, CO2 mitigation can only happen by developing low-carbon H2 sources (water electrolysis instead of SMR) and by implementing CCS. New ammonia production processes are also studied in order to create an improved disrupting process. Current alternatives require high electrical input and/or temperatures to produce ammonia via electrochemistry, either directly from N2 with water, in a two-step process where N2 reacts with H2 produced by electrolysis or a Li-mediated three-step cycle where the hydrolysis of Li3N facilitates the production of NH3 [177, 178]. However, these new processes are still energy-intensive and their scalability is yet to be demonstrated.

-

Dehydrogenation

Ammonia decomposition was historically achieved at high temperatures (>400 °C) on Fe or Ru transition metal catalysts supported on alumina due to the endothermicity of the process (9) [179, 180]. (9)

(9)

The decomposition rate is determined by the desorption of N2 that is dependent on the active metal (Ru > Ni > Rh > Co > Ir > Fe ≈ Pt > Cr > Pd > Cu ≈ Te, Se, Pb on Al2O3), the support (basic and conductor like Al2O3, MgO, CNT, …) and promoters (electron donors on Ru like K > Na > Li > Ce > Ba > La > Ca > pristine) [181–183]. NH3 shows promises as a H2 carrier, but its implementation for onboard applications is limited by the incompatibilities between NH3 and the PEM-fuel cell (PEM-FC) (high decomposition temperature, membrane poisoning, catalyst cost, NH3 toxicity and corrosivity) [184]. However, these NH3-PEM-FC incompatibilities can be partially lifted with an SOE-Fuel Cell (SOE-FC) [185]. Finally, NH3’s most practical application could be massive energy transportation to transport energy on an intercontinental scale.

4.2.4.2 Methanol

Methanol is one of the most produced chemicals worldwide with up to 164 million tons per year as a number of key industrial processes rely on it to produce high-value chemicals such as formic acid, formaldehyde, esters, ethers, olefins, and others [186–189]. From an H2 storage perspective, MeOH has attracted a lot of attention owing to its excellent gravimetric density of 12.5 wt.%H2 and volumetric density of 99 gH2/L. In addition, due to its only carbon, β-elimination cannot take place, limiting the number of potential side reactions.

-

Hydrogenation

MeOH formation from either CO (10) or CO2 (11) with Cu-based catalysts at high temperatures (300–450 °C) has been reported and patented many times since the 1960s [190–194]. (10)

(10)

(11)

(11)

However, the harsh temperature conditions used in these processes furthered the research of processes with milder conditions. Nowadays, new production processes of MeOH from CO2 are emerging, like biogenic synthesis [195], amine/alkaline- [196] or acid-assisted [197] CO2 reaction, formic acid disproportionation [198], and gas–solid phase [199], but the scalability has yet to be demonstrated.

-

Dehydrogenation

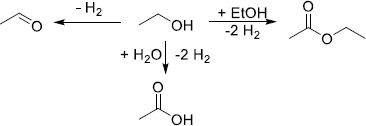

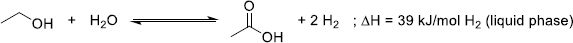

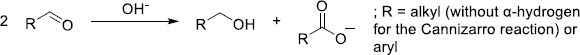

MeOH non-oxidative dehydrogenation is a multi-step process that requires the presence of water. A first H2 equivalent can be retrieved by its dehydrogenation to formaldehyde (12), then, after the addition of water, 2 other H2 equivalents can be recovered to produce CO2 by the equations (13) and (14), yielding the overall equation (15). (12)

(12)

(13)

(13)

(14)

(14)

(15)

(15)

The dehydrogenation can catalyzed by heterogeneous catalysts based on Co, Ni, Cu, Pd, Ru, or Ir at temperatures superior to 200 °C [200]. A careful monitoring of the reaction conditions is necessary as the by-production of CO during the dehydrogenation could prove fatal to PEM-FC [201]. Despite its good compatibility with the current infrastructures and good biodegradability, MeOH has still a few barriers to overcome as its boiling point is low (64.7 °C) and its flammability and toxicity could prove too dangerous for public usage [202].

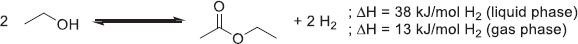

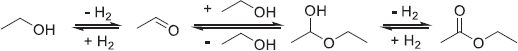

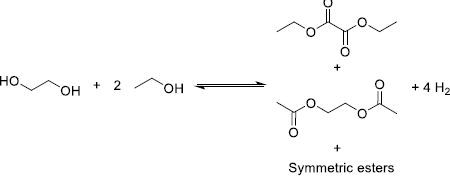

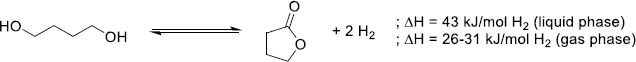

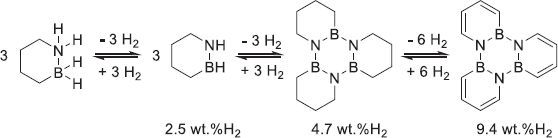

4.2.5 Liquid Organic Hydrogen Carrier (LOHC)

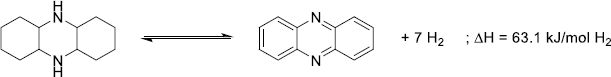

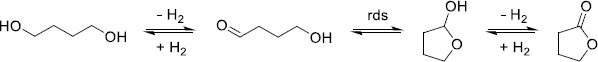

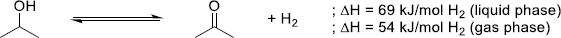

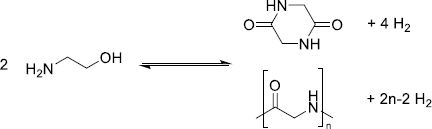

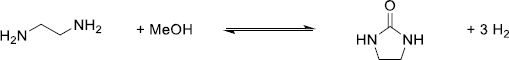

The Liquid Organic Hydrogen Carrier (LOHC) technology was developed in the 1970s to store the excess of nuclear electricity via water electrolysis in the form of automotive fuel [203, 204]. Recent developments and environmental considerations promoted this technology as a mean to store vast quantities of energy (GWh to TWh ranges) for a long time duration (seasonal). Much like the circular hydrogen carriers, the LOHC are liquid molecules able to store and release H2 at a desired place and time by catalytic hydrogenation and dehydrogenation reactions to respectively load and unload H2 (Fig. 12) [205]. However, both forms are liquid, which facilitates the separation of H2 and the LOHC during the dehydrogenation.

Storing H2 by covalent bonds on an organic liquid improves the handling and safety of the energy sector and retains similar volumetric densities compared to traditional physical systems, circumventing the need for heavy gas tanks and other cooling devices [206, 207]. The liquid phase is also advantageous as the reaction can proceed without the dilution of the H2 carrier in a solvent. In addition, most LOHCs are oil-like structures that can be easily transported by the current oil and gas infrastructures with small modifications to the system, eventually diminishing the implementation cost of the technology. Finally, social acceptance of the LOHC as a mobility option is favorable as the carrier system is similar to currently employed fuels [208].

Different criteria have been proposed to assess the potential of a LOHC. The energy efficiency is often addressed through the dehydrogenation enthalpy value. Classic LOHC systems have comparatively high enthalpy values (between 50 and 75 kJ/molH2) while the US Department of Energy (DOE) aims for 30–44 kJ/molH2 so that the H2 equilibrium pressure reaches 1 bar between −40 °C to 60 °C [209]. Like the other H2 storage systems, the gravimetric and volumetric energy densities highlight the energy storage efficiency with ultimate targets of 6.5 wt.%H2 and 50 gH2/L for a complete on-board system respectively. An excellent stability (>99.9%) of the LOHC is also required in order to avoid the replacement of the carrier [210, 211]. Finally, the LOHC must also answer to other application-dependent criteria such as a high liquid temperature range, its availability or ease to mass-produce from preferentially renewable feedstock, its cost, the H2 gas flow and quality on release (especially for fuel cells), the carrier toxicity and biodegradability [212]. It is worth noting that the properties of the LOHC can be heavily modified depending on the application and the time scale of storage. For example, a mobility application for individual transportation vehicles would mainly require high gravimetric and volumetric densities as well as a good cycling capacity and low dehydrogenation temperature while stationary systems (off-grid system) would be principally driven by the cost of the LOHC and its catalysts. Lastly, massive energy storage (seasonal storage) or a global energy system would necessitate both a low system cost and high densities.

The LOHC system possesses numerous advantages, but also drawbacks compared to other technologies. One major bottleneck is the toxicity of the LOHC molecules, similar to that of currently employed fossil fuels. Moreover, the classic LOHC systems are oil derivatives, so the development of bio-based structures would be preferential to completely remove fossil feedstocks from the LOHC technology. Besides, the catalysts used for the hydrogenation and dehydrogenation reactions are generally based on Platinum Group Metals (PGM) that are rare and expensive. Finally, the stability of the LOHC structures is a major concern, especially after multiple hydrogenation/dehydrogenation cycles with multiple side reactions occurring such as hydrogenolysis, cracking, and isomerization.

The next part of this literature review will focus on key molecules for the LOHC technology and the development of the associated heterogeneous catalytic systems and conditions for both the hydrogenation and dehydrogenation reactions. In addition, chemical functions able to store and release H2 will also be reviewed in order to broaden the perspective of LOHC structures.

To this date, no normalized procedure has been developed yet to compare reactions performed in different conditions like the temperature, pressure, reaction atmosphere, catalytic loading and composition, reactor type, and so on. In consequence, as the performance of the reaction is highly dependent on these parameters, it is often difficult to draw an easily generalizable conclusion. Whenever possible, key points were summarized in the introduction and conclusion of each part.

Finally, we would like to report some recently published reviews on the topic [212–216].

4.2.5.1 Cycloalkanes

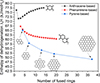

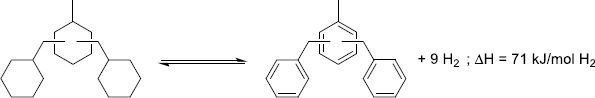

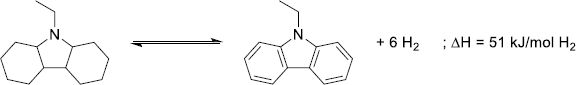

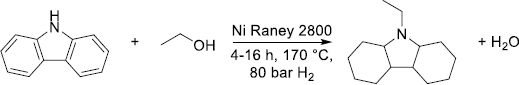

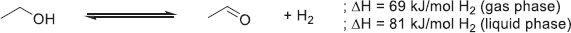

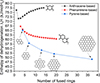

Cycloalkanes have been the first structures studied for the LOHC technology, as homocyclic structures are cheap and readily available due to their presence in the oil refining processes. Moreover, the dehydrogenation of homocyclic structures is facilitated by the aromatization and the specificity of the C–H bond-breaking over C–C bond-breaking. Thus, the development of selective catalytic systems has been reported since the 1910s with seminal work from Zelinsky [217, 218]. From a thermodynamic standpoint, most aromatic structures have dehydrogenation enthalpies in the 50–80 kJ/molH2 range. In addition, conjugation in polyaromatic systems diminishes the energy needed d/uring dehydrogenation, with the exception of anthracene-based systems that see their dehydrogenation enthalpy increase after three conjugated cycles (Fig. 13).

|

Figure 13 Dehydrogenation enthalpies calculated by the PM3 semi-empirical method as a function of the number of fused rings [219]. |

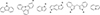

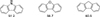

Clar’s rule links the stability in fused polybenzoic structures to the number of its stable sextets [220, 221]. Thus the stability increases from anthracene-type to phenanthrene-type to pyrene-type structures (Fig. 14). Moreover, anthracene-type structures produce Clar structures with a unique sextet but an increasing number of benzene rings, inducing the destabilization of larger structures.

|

Figure 14 Clar structures for 4 fused rings: anthracene-type (left), phenanthrene-type (middle), and pyrene-type (type). |

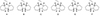

|

Figure 15 Influence of the size of the ring, the presence of N atoms, and their number on the enthalpy of dehydrogenation (kJ/molH2) [325]. |

Interestingly, graphene materials possess the best thermodynamic properties of polybenzylic structures, reaching theoretical dehydrogenation enthalpies in the 34–46 kJ/molH2 range [219]. However, due to their solid state, high fusion point, and low solubility, efficient hydrogenation and dehydrogenation of such materials are yet to be achieved [222, 223]. In addition, steric hindrance in fused ring systems is detrimental to the hydrogenation and dehydrogenation as reactivity limitations arise at the nods on the rings due to poor accessibility and the formation of less reactive isomers. In comparison, linearly linked hydrocarbons were shown to be more kinetically active [224].

Whilst numerous aromatic molecules have been tested for the LOHC technology, this work will focus on the most studied ones, i.e. the couples methylcyclohexane/toluene, decalin/naphthalene and perhydro-dibenzyltoluene/dibenzyltoluene. Benzene, benzyltoluene, fluorene, biphenyl and their respective hydrogenated counterparts will not be discussed due to the lack of significant system variations with the methylcyclohexane/toluene, perhydro-dibenzyltoluene/dibenzyltoluene, or decahydronaphthalene/decalin couples and the scarcity of development compared to the latter.

4.2.5.1.1 Methylcyclohexane/Toluene (MCH/Tol)

Due to its good gravimetric and volumetric densities (resp. 6.2 wt.%H2 and 48 gH2/L), abundance, low cost (0.3 €/kg), reactive simplicity, lower toxicity compared to the cyclohexane/benzene LOHC couple and lower computational cost compared to bigger LOHC like dibenzyltoluene, MCH/Tol is often used as a model carrier for the LOHC technology [213]. In addition, industrial development by the Chiyoda corporation has recently renewed interest in its research [225]. Recently, a conglomerate composed of Chiyoda, Mitsubishi, Mitsui, and the Japanese government demonstrated the feasibility of massive H2 transportation by ocean tankers with the MCH/Tol LOHC couple from Brunei to Japan.

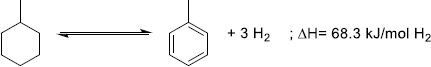

(16)

(16)

Historically, extensive research was conducted on the Methylcyclohexane–Toluene–Hydrogen (MTH) system for both mobile and stationary applications from the late 1970s to the late 1990s [205, 226]. Indeed, it was first proposed as an H2 fuel for automotive mobility in 1975 by Sultan and Shaw but was deemed inefficient compared to gasoline [203]. Taube and Taube proposed the MTH system again in the early 1980s as a solution to store excess nuclear power for automotive transportation [204]. Concomitantly, several pilot trucks were conceived to support the development of this technology [205, 227]. While the dehydrogenation reaction was not perfectly selective, this issue was circumvented by burning a fraction of the toluene or the impurities to kick-start and maintain the endothermal dehydrogenation. As the dehydrogenation is supposed to happen during times of low energy availability, lowering the energy consumption during the dehydrogenation is key to designing energy- and cost-efficient systems.

Further developments highlighted that the total catalytic oxidation of less than 10% of the produced Tol covered the complete calorie consumption of the dehydrogenation and a minimum of 6% could be in principle achieved by further optimization [228]. Similarly, extracting a portion of the combustion heat produced by an H2 thermal engine could compensate for the dehydrogenation enthalpy [229]. Moreover, this approach would be ineffective in the case of a PEM-FC engine due to its lower operating temperature. Finally, due to the low boiling point of MCH and Tol (resp. 100.9 °C and 110.6 °C), the dehydrogenation is a gas-phase reaction that is hence thermodynamically limited by H2 accumulation in closed systems [230]. Therefore, catalytic Pd–Ag membrane reactors were proposed as an answer to separate H2 from Tol during the reaction and push the thermodynamics forward [231]. Nevertheless, more development is required on these systems to reduce the amount of precious materials and to enhance their long-term stability in operating conditions [232].

-

Hydrogenation

Hydrogenation of cycloalkanes to aromatics was first achieved in 1911 and 1912 by Zelinsky with Pt and Pd catalysts supported on Al2O3 at 300 °C and 1 bar H2 [217, 218]. Since then, Ru/Al2O3 was shown to be the best monometallic catalyst for the hydrogenation of Tol to MCH, with extensive research on Pt, Ir and Rh based catalysts over the last three decades [233–235]. In addition, Ru presented a synergistic effect when doped with Pt [236]. Synergies were also studied for Pt, Pd, and Pd–Pt catalysts supported on Al2O3 to no avail [237]. However, alloying Pt and Pd increased the sulphur resistance of the catalyst at a temperature above 200 °C, while a rise of the support acidity increased the sulphur resistance at low temperatures (120 °C) [238].

Atmospheric pressure hydrogenation of Tol was also achieved by non-noble catalysts such as Ni/Al2O3 at 170 °C with perfect selectivity. Temperatures above 170 °C favored the desorption of H2, directly hindering the system kinetics [239]. Multimetal NiCoMo supported on zeolites allowed for the conversion of Tol to MCH at 200 °C and 20 bar H2. Side reactions such as ring contraction were observed in trace amounts [240]. Moreover, the hydrogen spillover effect, i.e. the migration of protons between the active metal nanoparticle and the support, also potentially played a role in the efficiency of the conversion. Indeed, hydrogenation with Pt/Al2O3 mixed/diluted with WO3/Al2O3 and solid acids showed improved conversion compared to the pristine catalyst due to the LOHC adsorption on acidic sites of the surface [241]. This effect was also observed on a Ru/NiCo/Ni(OH)2–Co(OH)2-nanoislands supported on carbon catalyst where the combination of the different sites achieved 100% conversion in liquid phase at 60 °C in 1 h for an activity ten times more superior to that of the equivalent Ru/C catalyst [242].

-

Dehydrogenation

Dehydrogenation of cycloalkanes to aromatics was also first achieved in 1911 and 1912 by Zelinsky with Pt and Pd catalysts supported on Al2O3 at 300 °C [217, 218]. However, these catalysts tended to deactivate due to preferential adsorption of the dehydrogenated products. Besides, side reactions like coke formation and dealkylation were observed at high temperatures (>350 °C) [243]. A series of noble metal catalysts supported on nitrogen-doped carbon showed that Pt was the most active catalyst, with the activity order Pt > Pd > Rh > Ir [244]. Extensive study of Pt supported on metal oxides and perovskites showed that 1 wt.% catalysts were more efficient than 3 wt.% catalysts, potentially due to the smaller size of the Pt nanoparticles [245]. Substrate modification with the addition of boron to a Pt/Al2O3 catalyst allowed for the tuning of strong acid sites into weak acidic sites, limiting the coke formation while retaining the stability of the metal nanoparticles on the substrate. This approach answered the lack of efficiency of alkaline addition that indistinctively covered all of the acidic sites and limited the dehydrogenation activity [246]. A Pt/Na–Y zeolite showed that hydrogenation or hydrogen transfer reactions happen during the dehydrogenation of methylcyclohexene, yielding both MCH and Tol [247]. As shown by previous contributions, the dehydrogenation rate-determining step was the desorption of toluene [248].

The synthesis of bimetallic catalysts is known to yield potential synergistic effects between the metals. Here, Pt–Re/Al2O3 showed a negligible influence of the H2 partial pressure on the dehydrogenation rate compared to Pt/Al2O3, indicating an alleviation of the thermodynamic equilibrium [249].

As the reduction of the active metal nanoparticle usually increases the activity of a catalyst, Single-Atom Catalysts (SAC) have a great potential to reach high kinetics. Recently, a Pt SAC supported on CeO2 nanorods was reported to catalyze both hydrogenation and dehydrogenation in continuous flow with activities 30 times superior compared to 2.5 nm Pt NP on CeO2 nanorods [250]. Similarly to Pt SAC, liquid metal solutions like Ga52Pt/SiO2 could atomically disperse Pt and maximize the gas-liquid interface, reaching up to 84.5% selectivity to Tol. While CO2 was observed, no coking formation was visible which was in agreement with the stable activity observed over 75 h [251]. Surface protonics are also a promising technique to lower the temperature of a reaction by applying an electric current [252]. Using a conductive Pt/TiO2 anatase catalyst submitted to a 5 mA electric current, the proton hopping specific properties of the support were increased, lowering the activation energy from 47.9 kJ/mol to 22.8 kJ/mol. Moreover, the dehydrogenation temperature could be decreased to 175 °C and the reaction equilibrium was displaced from 25% to 37% conversion [253]. As numerous effects occur simultaneously due to the specific nature of the TiO2 anatase support and electricity (Joule heating, etc.), more work is required to rationalize the effective influence of an electric field on dehydrogenation.

Non-noble metals are being heavily scrutinized as they may present an opportunity to replace critical and expensive PGM at usually the cost of higher catalytic loadings. The dehydrogenation of MCH to Tol was catalyzed by 20 wt.% Ni/Al2O3 catalyst, reaching a stable 92% conversion during 175 h on stream [254]. Further work on bimetallic Ni–M catalysts was pursued with Zn, Ag, Sn, and In. The Ni–Zn bimetallic catalyst showed a reduced activity (32.2% instead of 36.2% for pure Ni/Al2O3) with an increased selectivity to Tol (96.6% and 66.9% resp.). Nevertheless, the performance was still mediocre compared to a Pt/Al2O3 catalyst that reached full conversion and almost perfect selectivity (99.9%) in the same conditions [255]. Interestingly, flow kinetics with the NiZn catalyst in atmospheric pressure Ar demonstrated the insensitivity of the system to the MCH partial pressure above 0.1 bar and even a positive effect of H2 for partial pressure up to 0.4 bar, indicating that the hydrogenation of a species on the catalyst was necessary for the dehydrogenation. The increased selectivity by Zn doping was linked to the inhibition of low-coordination sites that were responsible for the C–C cleavage of the methyl group [256].

-

DFT

Computing techniques like Density Functional Theory (DFT) have been extensively used to rationalize and predict the reaction mechanism as well as propose catalyst modifications. A thesis on the dehydrogenation mechanisms of MCH on sub-nanometric Pt/Al2O3 proposed a DFT modeling coupled with kinetic experiments to rationalize the elementary steps during the dehydrogenation. DFT modeling showed that the cleavage of all C–H bonds was preferred compared to the migration and recombination of the protons. In addition, it exhibited the interactions between the LOHC and the support. Finally, the rate-determining step was difficult to assess due to the similar energies of either the third C–H bond cleavage or the desorption of Tol as often postulated in the literature [257, 258]. Predictive DFT was also used to estimate the influence of Sn-doping on a Pt/Al2O3 catalyst. The synthesis of an Sn4Pt phase could enhance the reaction kinetics due to lower activation energies compared to pristine Pt [259]. Lastly, DFT modeling showed that low-concentration of promoters (<1%) like Si, P or Se could in principle boost the dehydrogenation similarly to the already demonstrated S additives. Higher concentrations of doping elements showed no lowering of the reaction energy [260, 261].

-

Conclusion

From a techno-economic standpoint, dehydrogenation is the bottleneck of the MCH/Tol system as high-performance and low-cost PGM-free catalysts need to be developed while continuous H2 purification of the outlet feed and lower temperature of reaction are also to be addressed. In particular, the hydrogen performance, i.e. the stability of the LOHC, over the cycling is the principal concern due to isomerization and C–C cleavage side-reactions. Moreover, the high energy consumption during the dehydrogenation could be circumvented by using industrial heat waste or SOE-fuel cell systems. The rest of the economic chain is already ready as all dedicated infrastructures are in place and may just need a slight retrofit to adapt to the physical characteristics of the LOHC (higher viscosity) [262].

4.2.5.1.2 Decalin/naphthalene (Dec/Nap)

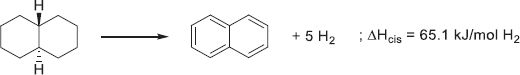

Decalin (Dec) is an inexpensive (0.6 €/kg) polycyclic fused-rings molecule that possesses high gravimetric and volumetric densities (7.4 wt.%H2 and 66 gH2/L resp.) [213]. However, naphthalene (Nap) is a solid up to 80 °C, which implies either incomplete conversion or dilution of the LOHC in a solvent in order to keep the system liquid. As calculated by Cooper, multiple fused rings diminish the enthalpy of dehydrogenation (Fig. 13) compared to free-standing or unfused rings [219, 263]. In addition, stereocenters are created by the fusion of the cycles, allowing for the formation of cis- and trans-hydrogenated isomers. Interestingly, the cis-isomer can undergo a ring flip reaction (17), while the trans-isomer has its conformation blocked and is the most stable isomer (18).

(17)

(17)

(18)

(18)

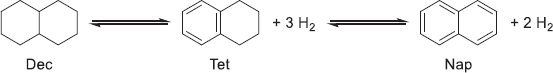

Similarly to the MCH/Tol couple, the boiling temperatures of decalin (185 °C) and naphthalene (218 °C) are lower than the reaction temperatures for both hydrogenation and dehydrogenation, implying either gas-separation and/or purification or thermodynamical limitations on the conversion in batch systems. In addition, a stable intermediate, tetralin (Tet), can form during the reaction (19).

(19)

(19)

-

Hydrogenation

As Nap is a homocyclic LOHC, its hydrogenation to Dec can usually be achieved by noble metal catalysts such as Ru, Pt, or Pd at high temperatures (>200 °C) [264, 265]. However, control over which isomer forms preferentially is dependent on the catalyst, the reaction temperature, and the pressure [266]. The effect of the support was shown by a series of Pt–Pd supported on (Al2O3)(1-x)/(CeO2)(x) (x from 0 to 0.5) catalysts used for the hydrogenation at 290 °C and 55 bar in a batch reactor. The presence of CeO2 improved the conversion up to 99.5% in 3 h and this effect was attributed to the adsorption of Nap on acidic sites (Ce4+) as well as modification of the redox properties of the acidic sites and additional spillover reaction [267].

Non-noble catalysts such as NiMo supported on Zr, Al, or Ti-Hexagonal Mesoporous Silica (HMS) showed a higher selectivity to Dec due to the modification of the Mo=O or Ni oxide active sites by the Zr, Al, or Ti dopants while the less active NiMo/Al2O3 converted Nap to the intermediate Tet [268].

-

Dehydrogenation

Nap dehydrogenation happens in the gas phase due to the necessary high dehydrogenation temperature. To circumvent that issue, liquid film state reactors were proposed as they favor reactive distillation that is known to facilitate dehydrogenation compared to “suspended-state” conditions due to the constant removal of the dehydrogenated products [269]. These conditions could be achieved either by batch reaction in a large volume [270] or by spray pulse reaction [271]. Unsurprisingly, Pt was also the best metal to catalyze the complete dehydrogenation to Nap [272]. Experimental dehydrogenation on Pt/C and Pd/C showed that Pt was more active for Dec formation while Pd was more active for Tet formation in the same conditions. These results were rationalized by DFT, showing that molecular alignment on the metallic surface was more important than the intrinsic activity of the metals [273]. For the time being, only Pt with additives such as W and Re achieved a conversion superior to 90% in 1 h at 280 °C. Moreover, this system fulfilled the required H2 rate of fuel cells for mobility applications (50 kW, roughly 0.47 mol H2/s for a fuel-cell efficiency of 45%). By integrating the amount of precious material in the catalyst, the H2 release rate for Dec was 0.88 gH2/gPt/min [202, 274].

In order to improve this rate, the synthesis of highly dispersed Pt nanoparticles was undertaken. A relationship was found between a small particle size and a high specific surface of the support [275], the preparation method of the catalyst with ion exchange, polyol method, and chemical reduction being more efficient than precipitation and impregnation [276] and the presence of additives such as Ti or Ca during the synthesis [277]. Acid-neutralizing additives also limited the formation of coke promoted by strong acidic sites of the support [270, 277].

Pt supported on carbon materials was shown to yield excellent results (85% conversion and 95% selectivity to Nap, 5% to Tet) in contrast to catalysts supported on Al2O3, potentially due to the spillover of hydrogen on the activated carbon support [278]. The microstructure of the carbon support had a significant impact on the dehydrogenation properties of Pt as shown in Carbon Nanofibers (CNF): a positive effect was observed in the order platelet > fishbone > tube where platelet corresponds to the edges of stacked graphene and tube corresponds to basal graphene [279]. These results were confirmed by DFT calculations that showed stronger interactions between Pt and the edge planes of the CNF compared to the basal plane of CNT [280]. In addition, the wettability, i.e. the affinity of the LOHC with the support, influenced the catalytic activity of the system. Pt supported on CNT synthesized with O modifications induced a better Pt dispersion but a worse performance due to the lower affinity between the apolar LOHC and the polar surface [279]. On the contrary, N modifications doubled the catalytic activity compared to pristine CNT as N-modified CNT retained a good surface polarity and favored electron transfers from the metal to the support, facilitating the Nap desorption [281]. Electron transfers were also observed for a Pt/MgAl2O4 catalyst, linking the positively charged Pt particles to the weakened adsorption of Nap. In addition, the edges of the Pt nanoparticles were identified as the active sites of the catalyst by DFT and size analysis experiments [282, 283].

The presence of two hydrogenated isomers induced interesting kinetics effects. Indeed, the cis-isomer reacted faster than the trans-isomer due to its flexible nature that can better accommodate the active site [284]. In addition, the cis-to-trans isomerization on the support acidic sites was favored compared to the trans-to-cis isomerization [274, 285]. As the cis-to-trans isomerization and the dehydrogenation were also kinetically controlled by the temperature, with isomerization being favored at low temperature and dehydrogenation at high temperature, the dehydrogenation of Dec to Nap was slowed down by the less reactive trans-isomer [286]. Unfortunately, no solution was found to improve the dehydrogenation kinetics in this aspect.